The Food Safety Modernization Act (FSMA) represents a sweeping revamp and upgrade to the nation’s food safety system. The Act’s seven rules not only change how the industry needs to approach food safety, but also they impose requirements in areas that have never been regulated before (e.g., foreign supplier verification).

What major misconceptions or areas of confusion do you see surrounding FSMA and its implementation?

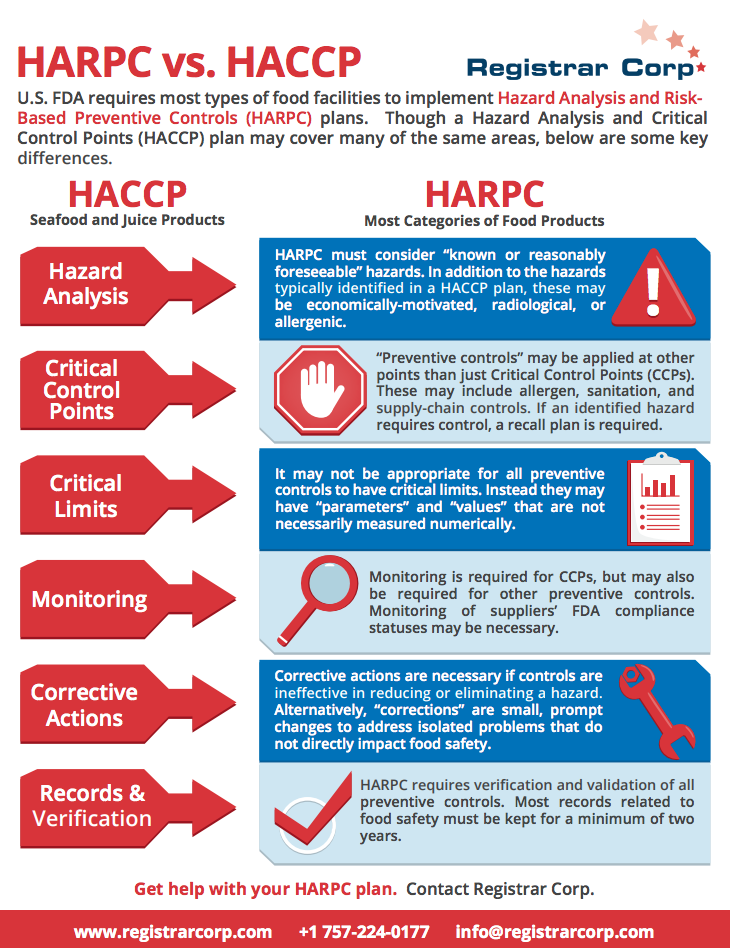

RB: We find many firms try to equate HACCP with FSMA and have the misconception that their existing HACCP plan is enough to cover all FSMA requirements. While a HACCP plan can be a good starting point for developing a HARPC Food Safety Plan, a HARPC Plan requires additional elements such as a recall plan and supply chain program. This is such a common misconception that we created a “HACCP vs HARPC” infographic to explain the differences.

Firms are still struggling to grasp the overall ramifications of FSMA and how it affects their business, whether it’s the need of a food manufacturer to have a comprehensive Food Safety Plan that identifies preventive controls, the produce operation determining whether their activities fall under the “farm” definition, or the importer obtaining the correct supplier verification documentation. In addition, compliance dates and exemptions/modified requirements for each regulation have been a confusing issue for firms.

In what areas of the food industry do you see the most confusion?

- U.S. importers – Importers have never had requirements such as these before, and thus it’s a large adjustment.

- Smaller processors tend to have more trouble than larger facilities that can afford to employ lawyers or a regulatory affairs team.

- International processors due to language barriers – both understanding the complex language within the rules and developing HARPC plans in English. While the plans aren’t specifically required to be in English, FSMA requires that the U.S. importer be able to “understand” the language within the HARPC plan. In many cases, this means the plan and related records must be in English.

Which rules are causing the most trouble?

Currently, we’re devoting a lot of resources to assist firms with the Foreign Supplier Verification Program (FSVP) rule. We probably get more requests for assistance simply because this is a new requirement for importers. They’ve never been required to verify that the food they import is produced in compliance with applicable FDA regulatory requirements.

What’s the timeline for FSMA inspections?

FDA has already begun conducting preventive controls inspections (as well as FSVP inspections). FDA has indicated that initially their inspectional approach will be to “educate and regulate” industry in regards to the new regulations. I would expect FDA to increase the number of preventive controls and FSVP inspections in the coming years.

How can companies at different stages of compliance make sure they’re ready when inspectors show up?

We advise our clients to be proactive and not wait until they receive a NOI (Notice of Inspection) from FDA to review their food safety procedures and documentation. They need to be familiar with the regulations that pertain to their business. Conducting a ‘mock’ inspection is a good way to determine your regulatory compliance and where improvements can be made. Registrar Corp offers a mock inspection service where we will send a food safety expert to a firm to help them prepare for an upcoming FDA inspection. Our Regulatory Specialists can also develop or review HARPC Food Safety Plans and FSVPs for FDA compliance.

Rick Barham acts as Director of Food Safety at Registrar Corp. He and his team assist food facilities to comply with U.S. FDA food safety regulations by reviewing HACCP and HAPRC Food Safety plans, conducting mock FDA inspections, and more. Registrar Corp provides compliance services for manufacturers, exporters, and importers regulated by the U.S. Food and Drug Administration.