In the past few years, interest in nanotechnology has grown exponentially. The official definition of nanotechnology, from the United States National Nanotechnology Initiative, is “science, engineering, and technology conducted at the nanoscale, which is about 1 to 100 nanometers.”

What does that mean for food?

The answer is “quite a lot.” Nanotechnology applications in the food industry include methods to extend shelf life, enhance nutritional value, and change flavor and sensory properties. (For an overview of the major ways nanotechnology is used in food, check out Food Safety Magazine’s Nanotechnology in the Food Industry: A Short Review.)

Nanotechnology also has implications for food safety. There are two aspects to this:

- Whether foods containing nanoparticles are safe to eat

- How companies can use nanotechnology to improve food safety

We’ll save the first aspect for another article (get a preview of the discussion in this Nature paper). For now, let’s look at a few exciting new nanotechnology developments that hold promise for boosting food safety.

Detecting foodborne viruses

Researchers at the University of Guelph have developed a new nanotechnology-based platform to rapidly detect very faint traces of foodborne viruses, like norovirus, rotavirus, and hepatitis. These viruses can get into food at any point in the supply chain, but since they’re not living organisms, they’re difficult to cultivate and detect.

The researchers invented a way to make gold nanoparticle films that can detect these viruses with 500 times more sensitivity than the methods that are currently used. Using this method, the researchers claim, it will be possible “to invent a simple, highly sensitive, and low-cost diagnostic technique for foodborne virus detection without the need for any complex equipment or special training on how to use it.” This could allow companies to detect viruses in livestock before they reach the food supply, as well as in humans before the infections spread too widely.

Read more in Food Safety Magazine.

Detecting harmful contaminants

In another application using gold nanoparticles, researchers at Oregon State University have developed a method to detect contaminants, for example, histamine in seafood.

Histamine can cause allergic reactions in people with histamine intolerance. Though it’s naturally present in many food items, histamine can build up to unsafe levels in certain fish if they’re not stored properly. It’s also very difficult to detect, which is where the gold nanoparticles come in. Using nanotechnology plus diatomite made from the fossilized remains of algae, the researchers were able to increase the signal intensity by almost tenfold.

Improving traceability

Tracing food throughout the supply chain could be about to get a lot easier.

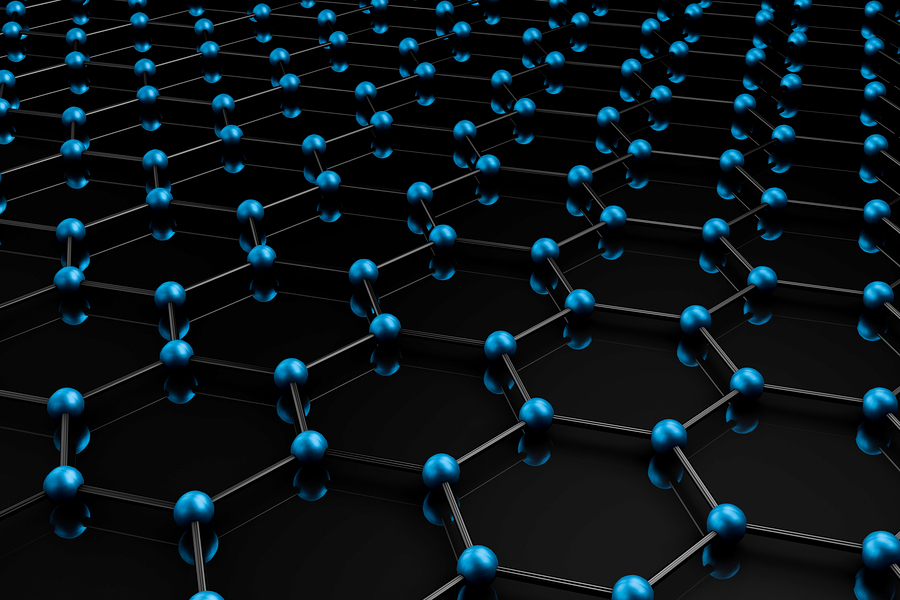

Researchers at Rice University have developed a laser technique to embed graphene patterns directly onto food products. In an interview with R&D Magazine, chemist James Tour explained it like this: “Instead of sticking a sticker on each apple, you can build an RFID [radio frequency identification] tag onto it, so you can put it directly on the food item.” The tags could also contain sensors that monitor the food’s storage temperature.

An advantage of this method is that the graphene is created from the food material itself. For example, potato skins and coconut shells can be easily converted into graphene, and Tour believes that any material that contains the right amount of carbon could be a contender.

Are you working on a new nanotechnology application? Or do you use nanotechnology in your products? We’d love to hear about it. Get in touch at press@foodindustryexecutive.com.