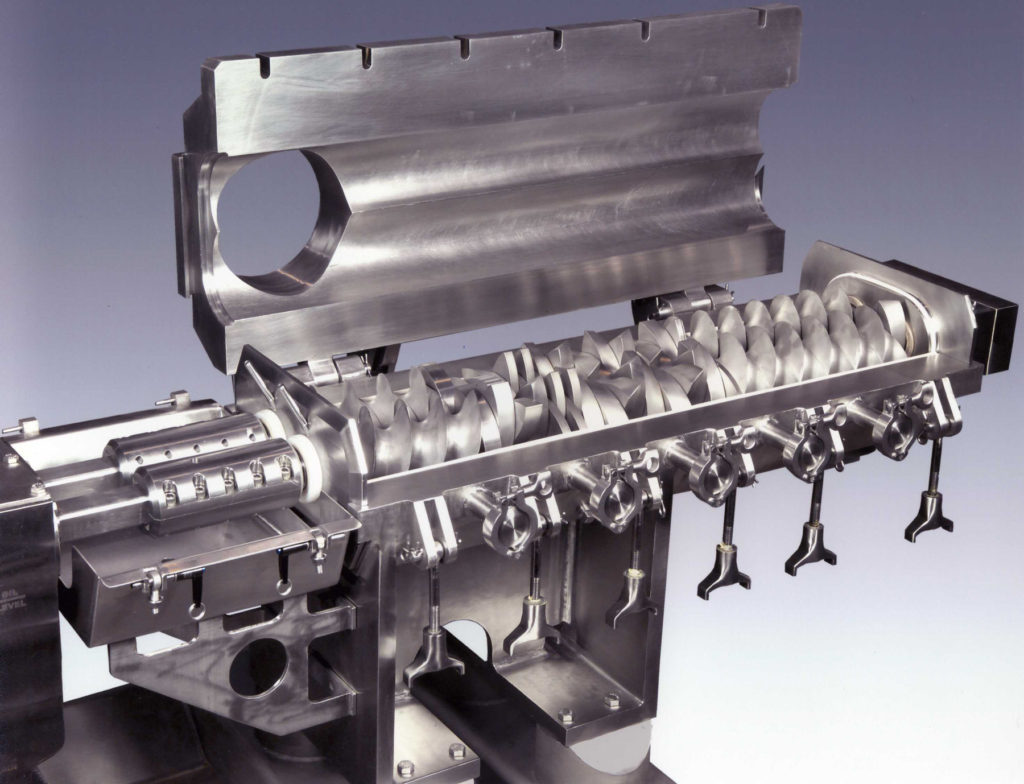

York, PA: Continuous Processors from process equipment manufacturer Readco Kurimoto, LLC, York, Pa. (www.readco.com), feature an optional clamshell barrel design that opens quickly and easily to access the paddles and screws for cleaning, inspection and/or adjustments to the configuration. Opening automatically at the push of a button, the proprietary clamshell barrel design uses hydraulic, pneumatic or electric power to raise the barrel and expose the interior while also locking the barrel safely in place. The novel Readco design eliminates the cranes, hoists and other equipment needed to access the screws and paddles using traditional barrel designs along with their need for extra floor space as temporary barrel storage during cleaning and maintenance.

Developed for food, plastics, chemical, pharmaceutical and other processors, the clamshell design speeds the changeover process and promotes complete cleaning to virtually eliminate the potential for cross-contamination. The clamshell design is suitable for automatically mixing, compounding, reacting, crystallizing, encapsulating, preconditioning, and other processes that require multiple powdered, liquid and viscous materials to be combined into a uniform, homogeneous product. The clamshell design is custom-engineered with the Continuous Processor for each installation to accommodate nearly any material including abrasives, corrosives, and materials requiring FDA-, USDA- and/or 3A compliance.

For a free brochure or more information, contact Readco Kurimoto, LLC, 460 Grim Lane, York PA 17406; 800-395-4959; or see www.Readco.com.