Countless samples are tested daily in analytical laboratories. The benefits of automation in this area is obvious: They make it possible to achieve faster results, higher throughput, fewer errors and lower personnel costs. In order to ensure smooth operation, high dynamics and precision are extremely important for the drive systems. We spoke to Dr. Aihua Hong about the requirements and developments in this market segment, for which she is responsible at FAULHABER.

In which industries does laboratory automation play a part?

Automated processes can be found in all laboratory areas, such as the chemical, pharmaceutical and food technology. The medical industry is an area in which there has been considerable growth worldwide. Automated solutions have been indispensable in this area for many years in so-called in-vitro diagnostics (IVD), i.e. the analysis of medical samples such as blood, urine and tissue. Test procedures are also becoming increasingly automated in the research laboratories of pharmaceutical companies in the development of new drugs.

What exactly is laboratory automation?

The degree of automation in the different laboratories varies considerably. It ranges from carrying out individual processes using stand-alone devices up to complete sample analysis in complex systems. The latter is particularly required in areas where large numbers of samples need to be examined in accordance with a standardised protocol and little flexibility is needed – such as IVD in the main laboratory of a hospital or in large laboratories for medical diagnostics.

Which processes are carried out automatically in these areas?

Almost the entire analysis process takes place automatically in these laboratories. It starts with the preparation of the blood samples in colour-coded sample test tubes. A scanner records the type of analysis that is required for a test tube, and ensures that it is picked out by a robot arm accordingly. Some of these samples are centrifuged in order to separate the constituents of the blood. The samples are then transported in special transport units to the actual analysis station, e.g. by conveyor belt or in a small trolley with a wheel drive.

What happens in the analysis station?

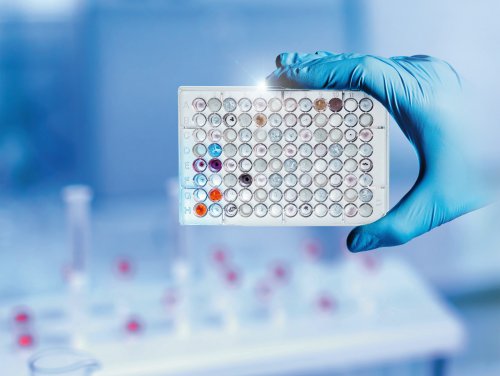

The sample is first identified by directing the bar code at a camera and having it read. Then the stopper is removed from the test tube, and some of the sample is removed. The test tube is then sealed again and archived for possible testing at a later date. The sample is transferred to a reaction vessel for the actual analysis, e.g. onto a test plate or petri dish. During the subsequent testing, the drive technology is mainly used for processes such as pipetting, liquid handling, mixing and stirring.

Which requirements have to be met by the motors?

Many different movements have to be be carried out during the entire process, and the demands made of the drive technology differ accordingly. The conveyor belts require large, powerful motors, and components that are as compact and lightweight as possible. Thanks to our comprehensive product range we can cover the entire spectrum, and can supply an extremely good solution for almost any requirement.

Can you give us some examples?

Many applications require a highly dynamic system for repeated start/stop movements such as pick-andplace and pipetting processes. Both speed and extremely accurate positioning are required when doing this.

Size and weight also play a part here: The drive for the upwards and downwards movement of the gripper arm or pipetting head can usually be found in the mobile component. It must therefore be extremely light and compact.

What are the advantages of FAULHABER motors?

The DC-micromotors of series 1524SR and 2224SR are particularly suitable for these applications. They have no iron armatures and are therefore much lighter and smaller than other models with comparable performance. At the same time, they are characterised by having extremely high dynamics. They are mainly used in combination with a series IE3 encoder, which only increases the overall length of the unit by two millimetres. High performance is therefore achieved with an extremely compact design.

Are there any other reasons for opting to use FAULHABER products?

It is extremely important to our customers place to have high-quality components so that their equipment will operate reliably for longer. They generate about ninety percent of their profit with the reagents that they sell with their devices for sample analysis. The service life of their equipment and the continuity of their reagent sales are therefore directly related.

Furthermore, the equipment for IVD has to undergo an expensive certification process before it can be put into operation. In order to avoid repeating this process, the replacement of existing devices with other models is avoided wherever possible. The availability of replacement parts therefore plays an important part as well.

If a FAULHABER component has to be replaced after a long service life, the customer can rely on the fact that it can still be obtained from us, even after many years.

https://www.faulhaber.com/en/markets/medical-laboratory-equipment/

###

Company box: The drive experts from Schönaich

About Faulhaber

FAULHABER is specialized in the development, production and deployment of high-precision miniaturized 3/4 and miniature drive systems, servo components and drive electronics with up to 200 watts of output power. This includes putting into effect customer-specific packaged solutions as well as an extensive range of standard products, such as Brushless Motors, DC-Micromotors, Encoders and Motion Controllers. The FAULHABER trademark is recognised worldwide as a symbol of high quality and reliability in complex and demanding application areas, such as medical technology, factory automation, precision optics, telecommunications, aviation and aerospace, and robotics. From the powerful DC-motor with a continuous torque of 200 mNm to the filigree micro drive with an outer diameter of 1.9 mm, the FAULHABER standard range can be combined in more than 25 million different ways to create the optimum drive system for a particular application. At the same time, this technological construction kit is the basis for modifications which allow to configure special versions to meet the specific needs of customers.

FAULHABER MICROMO LLC

Nicole Zipp – Marketing Manager

14881 Evergreen Ave

Clearwater, FL 33762-3008

USA

Nicole ZIPP

Phone: +1 727 572 0131 Ext. 215

marketing@micromo.com

www.faulhaberUSA.com