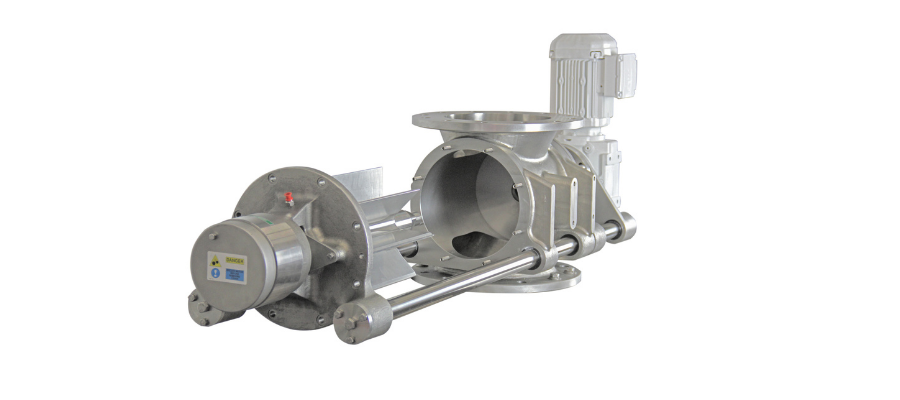

Gericke HDMF Valves Invite 360-Degree Access to Rotor Without Tools

Somerset, NJ: USDA-approved HDMF Series rotary valves from process equipment manufacturer Gericke USA, Somerset, NJ (www.gerickegroup.com), feature a proprietary rail locking system that automatically secures the rotor in place when extracted from the housing for safe, easy cleaning. Ideal for use in pneumatic conveying systems transporting powders, granules and other dry materials that may cake or require frequent inspection and/or cleaning, the HDMF rotary airlock valves set the rotor on parallel slide rails that allow the rotor to be quickly accessed and removed in seconds without tools. With its companion rotor tray in place during cleaning, the HDMF valves permit the rotor to rotate freely while still secured to the end cover for safe, 360-degree access, complete cleaning, and confident visual inspection without removal from the processing line.

Comprising six models in a wide choice of configurations, the sanitary HDMF Series valves earned USDA certification for use in food and dairy processing and include stainless steel construction with polished internals and externals as standard. The Gericke HDMF rotary valves are designed, manufactured, tested and inspected at the company’s headquarters and delivered ready for installation with a one-year warranty included as standard. Product and performance testing using the HDMF valves are offered at the company’s New Jersey test center.

For more information, contact Gericke USA, Inc., 14 Worlds Fair Dr. Suite C, Somerset, NJ 08873-1364; 855 888-0088; sales.us@gerickegroup.com; or see www.GerickeGroup.com.