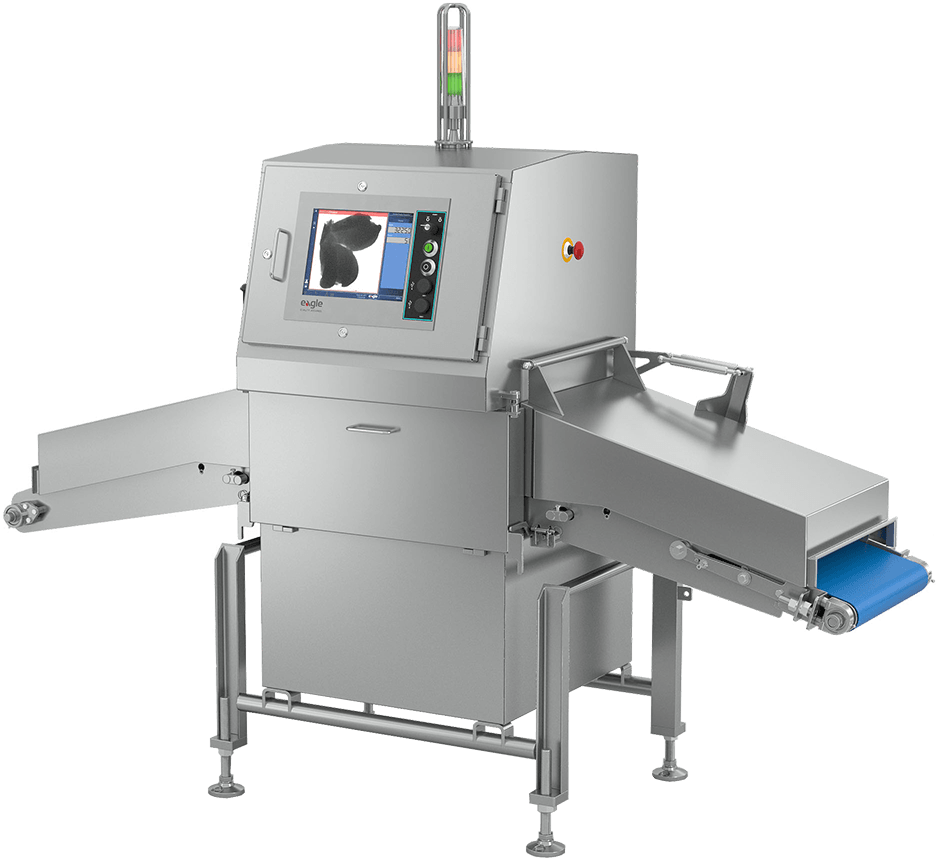

ABM Equipment doubles industry-standard capabilities with Eagle Product Inspection technologies

Vancouver, WA – ABM Equipment is detecting foreign material half the size previously possible for the industry using new hardware and software from Eagle. A mix of improved detector boards, generators, and algorithms have improved detectability across the board, making stainless steel detectable at 0.3 mm in many products.

Originally developed for the poultry industry, where bones are becoming finer and less calcified as practices change, the new solution, called “PXT”, was intended to be the best solution for one of the market’s most difficult applications. To do this the generators’ beam geometry was modified and the detection nodes (diodes) were placed closer together—reducing the spaces through which contaminants could slip. With more data to work from, the algorithms were also restructured to more accurately identify contaminants and reduce false rejects.

Initial tests were surprising, even to ABM Equipment. “We knew it was going to be better, we just didn’t know by how much,” said Jeff Walling, Co-Owner of ABM Equipment. “We took the [PXT] in a head-to-head against the industry’s other top players and blew them out of the water. Even the smallest test contaminants—the ones meant to make the machines fail—were detected at 100% accuracy. We just didn’t have contaminants small enough to see how far it could go. And that’s when the light came on.”

Since its launch, ABM has applied “PXT” to other products and documented the same results. “This is a quantum-leap for the industry,” said John Cassa, Co-Owner of ABM Equipment. “For the past few decades every player in the space has been pretty comparable. One company may perform better with this contaminant or that product, or they might get real tight specs on a specific application. They might see 0.3 mm stainless steel in cheese, for example, but then that’s all they can see. We’re getting unheard-of specs on everything—metal, bone, glass, plastic, stone, item weight, fill level, whatever. Even mass measurement and item count have improved dramatically.”

ABM Equipment is Eagle’s principal distributor and product-development partner. They helped develop a number of applications including the pipeline and meat chub solutions and have produced a software package which simplifies machine validations, product rework, and image retrieval to combat false liability claims.

To learn more, visit abmxray.com/pxt/ or contact Sam Cassa at 360-690-6481, or ncassa@abmequipment.com