For Immediate Release:

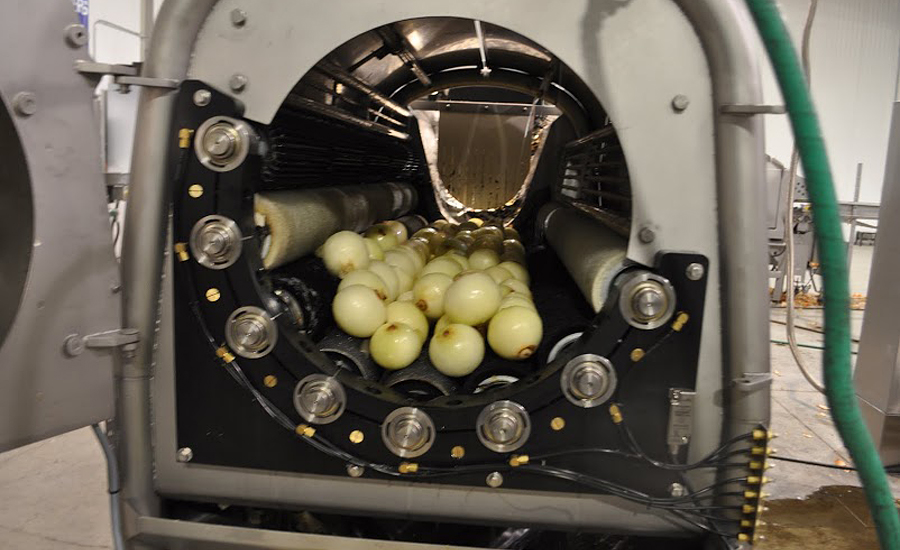

New machine uses a flame tube to burn the skin off of onions, pasteurizing the surface for enhanced safety and significantly reducing product loss compared to traditional cutting methods.

BRISTOW, OK – 2/19/2016 – Unitherm Food Systems today announces the receipt of U.S. Patent No. 9,215,892 B2 for its new system and method for pasteurizing the surface of a food product. The new machine uses a flame tube to remove the skin and outer layer of an onion before passing the onions through a cold bath to cool. The pasteurized and washed product retains the same color and flavor of the original product, while also increasing yield and reducing the risk of contamination. The patent was filed in August 2013 and approved on December 22, 2015.

Traditionally, onions are processed using a top and tail cutter, which can introduce contamination and results in product loss of up to 30% by weight. Unitherm’s new flame pasteurization system solves these problems and has no impact on the product’s appearance or taste.

Traditional Top & Tail Cutting System |

Unitherm’s Flame Pasteurization System |

| High risk of contamination Every onion passes through the same cutting machine. If a single onion is contaminated with Listeria, the contamination can easily spread to all subsequent onions passing through the blades. |

Potential for contamination eliminated The machine burns off the skin and pasteurizes the onion underneath, skipping the top and tail cutter. The moment an onion leaves the machine, it is pathogen-free. |

| High product loss This method can remove up to 30% by weight of the onion yield. |

Substantially higher yield This method removes only 5% by weight of the onion. |

| Limited production capability Each line of production can send only a limited number of onions through the cutting machine at a time. |

1 machine = 9 traditional production lines A single continuous belt can hold nine to ten onions in line with hundreds of onions passing through the system at once. The full pasteurization process takes only 45 seconds, and a single machine can process 12,000 lbs of product per hour. |

After pasteurization, onions can immediately be put into the dicing machine. Several companies already use the flame pasteurizer, including Garden Fresh, which uses it to prepare onions for salsa, and Simplot, which uses the machine in its Tasmania operations.

Unitherm Founder and CEO David Howard commented: “With new food safety regulations coming into play, there is now much more scrutiny of food coming from the earth. This has resulted in more recalls of vegetable products. With my machine, processors know they aren’t bringing any pathogens into their system. Because of the substantially higher yield, our new system can pay for itself within 12 months. What’s more, the onion that comes out of the pasteurizer tastes exactly the same as the onion that went in.”

About Unitherm Food Systems

Unitherm is known for its innovative approach to the design and creation of thermal food processing equipment and systems to maximize yields while enhancing safety and profitability. From cooking and chilling to pasteurization and freezing, Unitherm provides best-of-breed continuous thermal food processing equipment to maximize quality, production efficiency, and safety. Visit Unitherm online at www.unithermfoodsystems.com.