Gericke Centrifugal Sifters Safeguard Product from Contamination

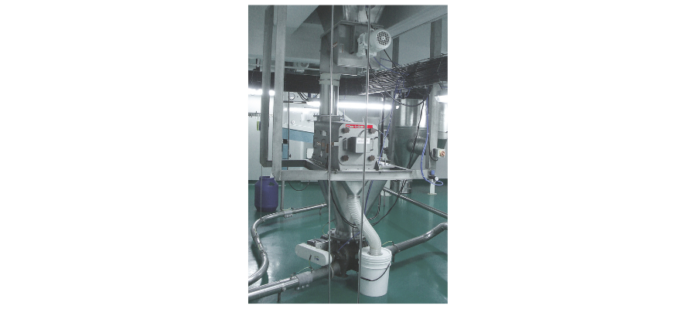

December 11, 2020 Somerset, NJ: GS Centrifugal Sifters from process equipment manufacturer Gericke USA, Somerset, NJ (www.gerickegroup.com), automatically capture and remove foreign objects from granular and powdered product streams to prevent contamination and safeguard downstream equipment. Installed at the silo, bulk bag discharge station or other storage unit, the GS Sifters pass the product stream through a rotating mesh screen sized to allow on-spec material to continue downstream while rocks, bones, metal parts, bulk bag pieces, and other foreign objects are blocked and diverted for analysis and disposal. Contaminants are safely removed, product quality assured, and downstream equipment protected from damage.

Ideal for protecting food, grain, chemical, pharmaceutical, mineral, and other products, the rotary sieves are offered in a choice of carbon steel, 304 stainless steel, or 316 stainless steel with a dust-tight housing and a range of surface finishes to meet sanitary and/or hazardous environment requirements. The sifters come with screens ranging in mesh sizes from 100 – 4,000 μm and a removable basket assembly for safe, easy, complete screen cleaning. The sifters may be tested in the company’s New Jersey test laboratory and custom models are offered to suit virtually any powder process.

For more information, contact Gericke USA, Inc., 14 Worlds Fair Dr. Suite C, Somerset, NJ 08873-1364; 855 888-0088; sales.us@gerickegroup.com; or see www.GerickeGroup.com.

Media Contact:

Rene Meira Medina

855 888-0088 x 805

rene.medina@gerickegroup.com