The last FSMA final rule has passed, and many manufacturers, especially the largest ones, may face a bumpy road to compliance. Safety is a primary concern, and food safety depends most on a clean environment.

Here are some basic equipment choices that will help make and keep your plant FSMA-friendly.

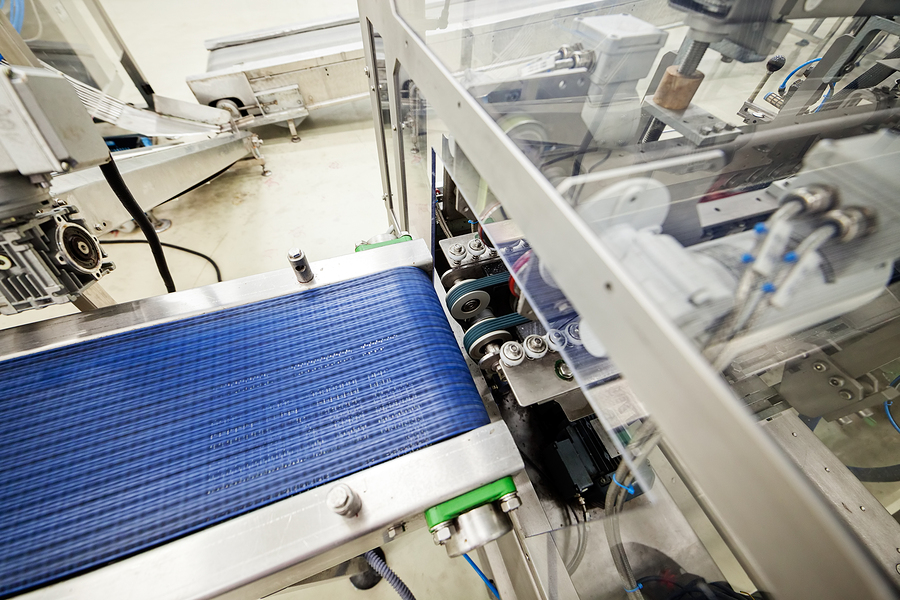

Conveyors

Conveyors are the spine of any manufacturing operation. If they’re harboring contamination, it can easily spread to all corners of your plant. Crucial elements of sanitary conveyors include full accessibility, catch-point-free design, and FDA/USDA-approved materials.

Sterilization and cleaning

To maintain FSMA-friendly environments, arm yourself with the right equipment for cleaning and sterilization. Steam-injection heaters that control water temperature and automated heating units set on programmable loops can ensure your sterilization is up to preventive controls rule standards.

Modular line elements

In addition to maximizing production, modular equipment systems can minimize downtime and improve food safety. Invest in systems that can swap out individual parts or sections for offline cleaning. Target and isolate areas of contamination before they spread through an entire line. Modular systems are also adaptable to changing production needs as you respond to ever-evolving consumer demands.

Automation

Human contact poses a certain level of safety risk to food products, so automating wherever possible will automatically cut down on some of that risk. Automated equipment can bring added benefits with self-cleaning features and machine-to-machine communication capabilities to streamline data collection and proactively identify and isolate safety hazards.

Track-and-trace tools

Under FSMA, one major key to prevention is documentation and authentication. Data collection equipment and processes are therefore crucial to your compliance. Clipboards won’t cut it anymore. Build traceability toolkits that include barcode printing and labeling, as well as data collection and analysis applications to track products throughout your supply chain. The benefits will extend beyond safety to increased consumer trust and engagement.

Whatever your plans for compliance, they need to include the right equipment. Employee buy-in at every level is also crucial for implementing preventive tactics, and people are more likely to support proactive, preventive measures when they have the necessary tools to help them do their job.