At IPPE 2022 in Atlanta, Georgia, Cabinplant A/S introduces the next generation of weighing and packaging solutions for the food industry. The fully automatic MHW SF Extreme breaks boundaries in the handling of sticky products used for the booming convenience food market.

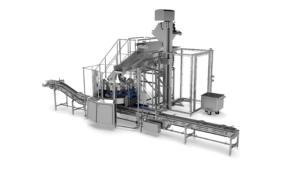

Cabinplant A/S, Danish and US-based innovative and global supplier of tailor-made food processing and weighing/packing solutions, is ready to create a stir at the next IPPE January 25-27, 2022. The company introduces the new, fully automatic MHW SF Extreme, which is aimed at the booming convenience food market and can weigh and pack extremely sticky products.

Further, Cabinplant will present the Multibatcher, which is ideal for weighing large portions of meat and poultry to reduce give-away and labour costs. With its highly automated process for portioning up to 75 lbs batches, the solution has the potential to send the meat processing industry into the fast lane.

Highlights at IPPE 2022:

New generation multihead weigher: The fully automatic MHW Extreme facilitates weighing and packing of sticky products, often used for the booming convenience food market

Multibatcher – innovative food weighing technology that increases throughput and reduces give-away and labour costs significantly when it comes to weighing and batching of large portions

Fully automatic MHW Extreme: Weighing/packaging of extremely sticky products

Increased automation has been limited by the widespread use of sticky ingredients in ready-to-eat products, as automated packaging plants have not been able to manage them. So far, the limit has been reached for fresh products such as chicken and fish. Stickier products have stuck to the weighing machine, but this challenge is solved by a new patented solution from Cabinplant – the Multihead Weigher SF Extreme.

The Multihead Weigher Extreme combines Cabinplant’s well-known screw-feeder combination weight with new scraper/weighing pans and a new processing solution, which ensures that the food is packed into trays on the conveyor belt. The MHW Extreme has a very compact design, which make it easy to fit into existing production areas.

The new multihead weigher makes it possible to fully automate the dosing and packaging of ready-to-eat meals, which includes sticky ingredients such as diced vegetables, onion rings, rice, pasta, tuna fish, mayonnaise, yoghurt, etc. These processes were previously performed manually or partially manually, without exact weighing.

– This is a technological breakthrough that breaks the boundaries of what has been possible so far with package lines and multihead weighers. Now the production of a large number of ready-to-eat meals can be fully automated, says Henning Ingemann Hansen, Director of Research and Development, Cabinplant A/S.

The MHW SF Extreme reduces the number of operator resources by 60-70 percent compared to similar packaging line of convenience products including sticky products.

– The MHW SF Extreme removes a major bump in food manufacturers’ roadmap, bringing a significant productivity jump and new level of accuracy in weighing of extreme sticky product mixes and reducing the labour force vulnerability of the production line significantly, concludes Michael Falck Schmidt, Sales Director at Cabinplant.

The end-product can be ready-to-eat meals packed in plastic trays, standing bags, etc. The cassettes can be replaced, which reduces the time for cleaning and changing to only 5-10 minutes and allows for frequent changes in recipes and packaging sizes at a time when the retail trade wants more varieties as well as more frequent and smaller deliveries.

Finally, during the pandemic the food industry has become aware of the vulnerability of labour-intensive production. The new weighing/packaging machine enables increased automation and reduces the food manufacturers’ risks of involuntary stoppages.

Cabinplant Multibatcher: Box packing in the fast lane

The Multibatcher is an automatic high-speed solution for weighing and packing of large portions of up to 75 lbs. It is the first batcher based on combinatorial weighing and an alternative to conventional batching and manual processes. The Multibatcher has the potential to significantly reduce give-away and costs through precision and speed.

The raw materials are weighed into partial portions in a number of pans which are combined into batches with a give-away down to 0.25-0.7%. This is a remarkably high level of accuracy compared to solutions like batching based on the top-up principle.

– The Multibatcher provides significant savings. The give-away can be reduced with up to 2000 lbs of meat on a daily basis for a processing line running two shifts and based on 3.5 oz or less give-away per portion, says Michael Falck Schmidt, Sales Director at Cabinplant.

The Multibatcher processes up to 12 batches per minute in batches of 1-75 lbs. The solution is tailor-made and can be fitted into existing packing lines or used as a stand-alone unit. The solution is suitable for all kinds of small or large products, including meat, meat by-products, poultry and fish products and comes in two versions with a pan volume of 5 or 8 gallons.

About Cabinplant

Cabinplant is a leading global provider of tailor-made processing solutions for the food industry. Focus areas are within fish & seafood, fruit & vegetables, meat & poultry, and convenience foods. Additionally, Cabinplant provides multi-head weighing and packing solutions for a wide range of industries. In close cooperation with the customers, Cabinplant develops, manufactures, and markets innovative complete food processing and weighing, packaging lines as well as single machines with built-in knowhow that optimize yield, throughput, and product quality.

Cabinplant is a global company with headquarters in Haarby, Denmark, and employs More than 300 people. Subsidiaries in Germany, Spain, Poland, and USA as well as a sales network of agents in more than 40 countries worldwide.

Founded in 1969 Cabinplant celebrated its 50 years anniversary in 2019. In 2016, the American industrial company CTB, Inc., a Berkshire Hathaway company, took over 80 percent of Cabinplant’s shares to back up further expansion including development of new products and partnerships.