Even with the availability of advanced technologies, food and beverage manufacturers have been slow to move deeper into the digital world. While some technologies have taken root, such as the use of virtual reality in the design build process, others, including robotics on the process line, are just finding a foothold.

In its 2020 Digitization survey, taken prior to the pandemic, CSB-System found almost

all participants – decision-makers of global food and beverage enterprises – think that technologies like IoT, cloud computing, artificial intelligence (AI), robotics, and Big Data are highly relevant for their business – in the future.

Well, thanks to COVID-19, the future is here.

With the travel bans and shelter-in-place requirements that were quickly enacted as the pandemic hit North America, many food and beverage equipment manufacturers realized they needed to amp up their use of digital technology to keep orders and projects moving forward. As a result, “hands-off” operating options quickly gained momentum and are on the way to becoming standard operating procedures (SOPs) in the food and beverage industry.

“I think that the current situation has accelerated the use of technology by a decade,” said Tom Garvey, president of Garvey Corporation. “The technology was there, and it was gradually being accepted by early adopters. But now, it’s often the only option.”

It should come as no surprise that the web and video conferencing category has seen a 500% increase in buyer activity since the beginning of the COVID-19 outbreak. A poll by TrustRadius found that 67% of companies are increasing their spending plan to invest in web conferencing software. This includes many companies in the food and beverage industry.

Let’s take a look at some of the innovative ways the industry is using this and other digital solutions.

Hands-off, eyes-on — Virtual FATs, installations, and service calls

When the pandemic hit, Garvey, which supplies conveying, accumulation, and automation services to the food, beverage, and pharmaceutical industries, found itself in sudden need of a virtual option to deliver factory acceptance tests (FATs), installations, and service calls.

Prior to COVID-19, the only time Garvey used digital technology for FATs was to send a video to a customer for approval. But this was the exception and only used for less complicated equipment. Like for most equipment manufacturers, the SOP at Garvey for FATs, installations, and service was in person.

Then in March, as the travel bans were put in place, Garvey was faced with the need to deliver orders that required FATs in order to fine-tune the equipment.

“These were complicated systems and we couldn’t just take a video and send it to the customer,” Garvey said. “The FATs are critical as we need to make any changes that the customer requests while the equipment is still in our factory.”

Although the customer couldn’t physically travel to Garvey’s plant in New Jersey, the Garvey team still needed to find a way to get the equipment in front of them. The answer was to deploy digital technology.

John Neil, Garvey’s plant manager, took the lead in equipping the company with the needed technology to work with customers digitally. He built a mobile station consisting of a tall rolling computer stand that contains a CPU, a monitor, and a high-end Logitech webcam with HD video, 10x optical zoom, and full remote capabilities.

This technology allows Garvey’s technicians and engineers, wearing headphones and sharing the camera feed, to provide multiple views and detailed close-ups of equipment in the plant. The customer joins using video conferencing software so they can communicate with the on-site team. Unlike for a traditional FAT, the entire meeting is recorded so that all parties can have a complete account of what happened.

“The tests are controlled by customers as to what they want to see,” Neil said. “We record what they see and then make a punch list of any changes that need to be made before the equipment is shipped.”

The virtual FATs have been critical to keeping business going during this time. “The technology is all there, but without people like John taking the lead in equipping us to do virtual FATs, we would not have been able to ship anything,” Garvey said. “This capability has allowed us to ship a lot of product.”

In the future, Neil anticipates that all of Garvey’s FATs, including in-person, will use the video equipment to record the inspection.

“We found that with the overhead camera and a technician getting inside the machine with an iPhone, we can see more than before,” Neil said. “Plus with the project management software Asana, we can create a media gallery with a live punch list folder that bridges the engineer, the customer, and the technician.”

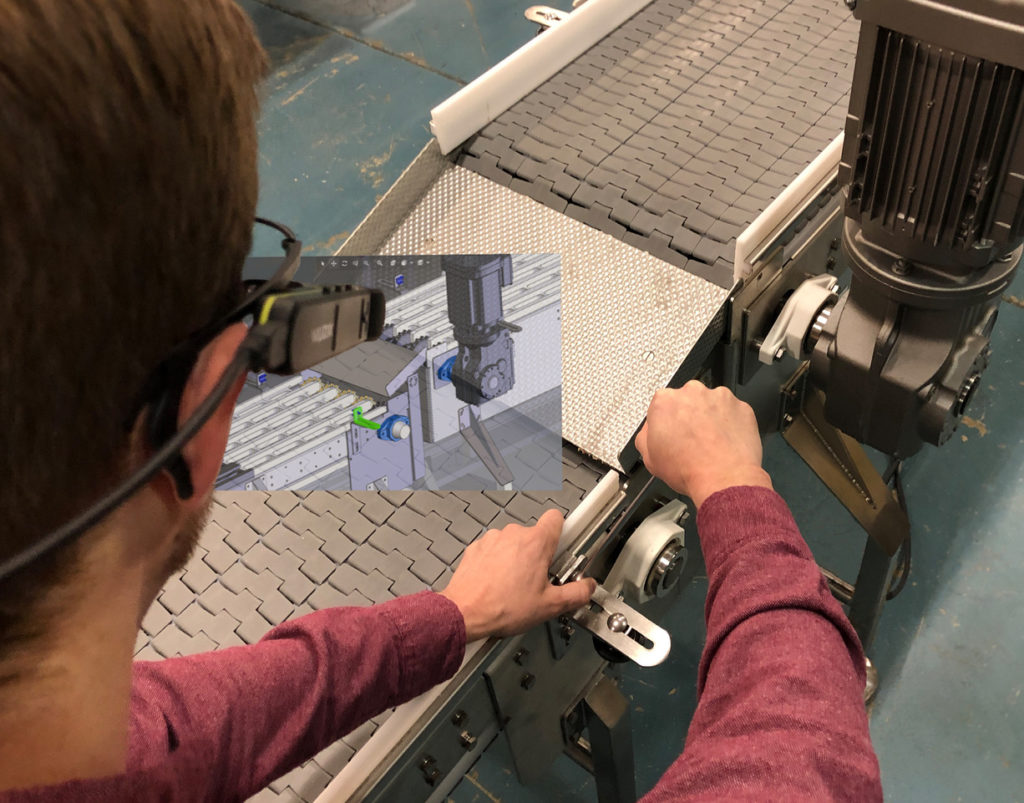

Garvey has also invested in equipment to facilitate virtual installations and service calls using augmented reality via a headset that enables their service technicians to see from the customer’s perspective. The headset has a screen that gives the feeling of a 7” tablet floating in front of the user, as well as a full audio and video system that allows the customer’s technician to go hands-free while being guided by Garvey’s engineer. The engineer can share not only a video feed of themselves directly to the headset, but also a feed of any program, white board, or screen on their computer. This provides flexibility to help the customer work through any situation.

“Their technician wears the headset that we provide,” Neil said. “We thought it would be more difficult to get the plant’s maintenance team to use these but have been pleasantly surprised. Once their maintenance guys get comfortable with the technology, they can see the potential savings to the company – time and money – and the value it adds to their jobs. They push for it.”

A virtual showroom

To ensure business continuity, TOMRA Food, a designer and manufacturer of sensor-based sorting machines and integrated post-harvest solutions for the food industry, developed a virtual showroom. Their Online Demonstration Room enables customers to follow demonstrations via a live video call, which allows them to test TOMRA’s sorting solutions before making an investment.

“We are going through a period of unprecedented disruption,” said Ashley Hunter, Senior Vice President and Head of TOMRA Food. “In this situation, our foremost priority is to ensure that we support our customers’ ability to maintain a consistent supply of quality food while keeping our employees and, by extension, our customers’ and suppliers’ staff, safe and well. These are challenging times for all of us, both on a personal level and for our businesses, but it is vital that we keep up our collective efforts to keep the global food supply chain operating effectively.”

TOMRA also leverages digital technology to support customers with their existing sorting equipment without visiting their sites by using its remote service and training tools.

“TOMRA Food’s overarching priority is to ensure the health and well-being of its employees, as well as its customers’ and suppliers’ staff,” Hunter said. “With all these actions, it is ready to help its customers navigate the challenges of this unprecedented crisis while protecting the safety of all the people involved.”

Taking the lab to the customer

Like Garvey, Gericke USA, a manufacturer of equipment and systems for bulk material processes, has started using various virtual platforms such as Facetime, Microsoft Teams, and Skype for FATs, installations, and service. The company also has deployed the technology into its test laboratories, including the one in Somerset, N.J. The test lab allows the customer to see how Gericke’s mixer operates using the customer’s ingredients.

“Normally, customers come into the lab,” said Rene Medina, Gericke USA’s managing director. “What we do in the test lab is, for example, if a customer wants to produce a ready-to-drink cappuccino mix, they ship the coffee, sugar, vanilla, milk, and other ingredients to the lab. We put them in our mixer and do the mixing. This allows the customer to see exactly how the mixer operates with their product.” Medina said. “Before all of this we would occasionally send the movie to the customer, but that was the exception.”

Digital solutions post-pandemic

Whether the use of these digital solutions will persist into the future is unclear. What we’ll likely see is some combination of old and the new, because, while the digital technologies provide cost savings, in-person interactions are still important.

“I miss customers coming into our facility,” Garvey said. “I’m selling the company when they visit the plant and that is important.”

Medina agrees. “I expect that we will continue doing this [virtual work] for a while, but things will come back to as before. People like to see and touch equipment, and I don’t believe this is a new normal. But it did give us a new experience and forced us to learn what was already there.”

COVID-19 has caused a massive amount of disruption, from the simplest things such as buying groceries to the complex process of building the equipment that’s used to make those groceries. It is a tough situation, but it drives companies to think outside the building and find ways to adapt.