Versatile Nibbler on Optional Casters Aids Flexibility

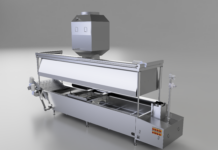

Somerset, NJ: The Nibbler lump breaker from process equipment manufacturer Gericke USA, Somerset, NJ (www.gerickegroup.com), features an optional mobility package that enables the size reduction machine to be easily moved upstream, downstream, or from one processing line to another. Devised to allow permanent integration or temporary installation without requiring investment in multiple machines, the mobile Nibbler may be used to achieve a consistent, desired particle size as material leaves the silo, hopper or bag station; in advance of a pneumatic conveying, milling or feeding system; and downstream of mixers, dryers and coolers for deagglomeration.

Set on a choice of heavy-duty, non-marking casters, the mobile Nibbler may be quickly cleaned for smooth product changeovers and rolled from one place to another within a batch process. A removable basket and screen invite full access to the interior for complete cleaning and confident inspection. Suitable for food, chemical, plastics, pharmaceutical, and other processors, the versatile deagglomerator automatically shears dry materials through a serrated screen at low speed with minimal heat for precise cutting down to 1 mm.

The mobile option is available on all seven models including on the FDA-compliant, hygienic, ATEX-certified, and custom models. The mobile Nibbler is available for testing in the company’s New Jersey test laboratory.

For more information or to schedule a test, contact Gericke USA, Inc., 14 Worlds Fair Dr. Suite C, Somerset, NJ 08873-1364; 855-888-0088; [email protected]; or see www.GerickeGroup.com.

Media Contact:

Rene Meira Medina at 855-888-0088 x 805 or [email protected]