By Richard Parmee, founder and CEO of X-ray inspection technology specialist Sapphire Inspection Systems

Inspection of food and beverages to ensure they are free of foreign bodies is a routine feature of factory production lines. But the latest X-ray inspection technology can do so much more than detect a fragment of metal or glass in a box of chicken nuggets.

Has a product got the correct amount of filling, for example – and is it evenly distributed within the product? Are there any missing or damaged items in a multipack? Is there a tiny speck of sauce trapped in the seal of a ready meal – letting in oxygen to spoil the food?

A new generation of inspection technology is offering unrivalled real-time insights into all aspects of food products – without disrupting traditional factory procedures and high-speed production lines.

When X-ray inspection first became available in the mid-1980s, its primary purpose was to replace the metal detectors that factories were using to detect stray fragments of metal in food products. The performance of the metal detectors was affected by a variety of factors such as temperature fluctuations, metalized packaging – and even the fat in cheese or meat.

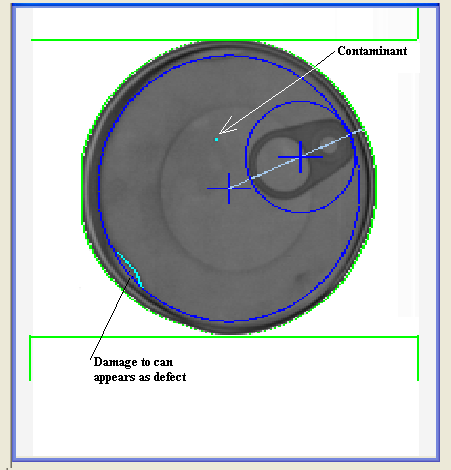

As well as overcoming these performance limitations, X-ray technology was found to be capable of detecting additional foreign bodies, including glass, bone, ceramics, stone, and certain types of plastic. It could even find such dense contaminants within a container of the same material – metal in metal, for example, or glass in glass – as the software was able to factor out the presence of material of uniform thickness.

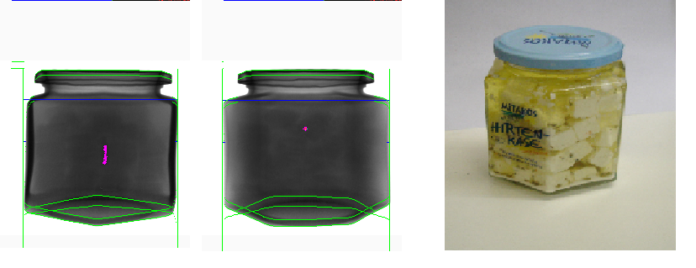

Further developments in image processing software now mean X-ray inspection systems can routinely mask out features that would otherwise be seen as a contaminant. The pull tab of a metal can, for example, could cause a false reject as it deviates from the uniform thickness of the main body of the can. But detailed information about the geometry of the can means the pull tab can be automatically located and defined as an area of lower sensitivity – giving a reliable means of inspection.

The latest image processing software can also cope with the variations in thickness and shape of glass containers. Glass jars, for example, can have ridges and bulges, they can be tapered, and the base can often be thicker. This all requires much greater tolerance from X-ray inspection technology.

Accurate and repeatable measurements of the mass of material within a particular region of a product is another useful feature of X-ray inspection. The technology not only checks the weight of an entire product, it can individually weigh a series of items within the product. So, in a pack containing six apple pies, the one pie with less filling than the others will be identified and rejected – even if the remaining five pies have slightly too much filling.

Molded chocolate bars with embedded wafers can also benefit from this aspect of the technology. If the wafer is missing, the molds get filled with chocolate, which is more expensive for the manufacturer – costing more than $700,000 per year for a typical production line producing between 4,000 and 8,000 bars per minute.

The same technique can also be used to check that each donut has the correct amount of jelly in it – or that a box of chocolates has the right chocolates in the correct positions. It can even check that your ready-to-cook meal has all the ingredients you need, or that your sushi lunch is not missing its chopsticks.

Seal inspection is another aspect of food processing benefiting from the latest generation of X-ray inspection technology. Once the protective gas mix has reduced the amount of oxygen inside the food packaging, a good seal is crucial to help the contents stay fresh for as long as possible. If a salad leaf gets caught up in the seal and is left sticking out of a packaged pasta salad, for example, it will breach the airtight seal and allow in oxygen – which will make the product spoil faster and lead to wastage and customer complaints. With the latest X-ray technology, two images are generated from a single detector – one optimized for the product and one for the seal area. It means even the tiniest speck of sauce trapped in the seal of a ready meal can be detected.

With the food processing market projected to exceed $4 trillion by 2024, the latest generation of X-ray inspection technology is playing a key role – providing a new vision for the future of the industry.

Richard Parmee is founder and CEO of X-ray inspection technology specialist Sapphire Inspection Systems. As well as designing bespoke solutions, Richard and his team provide a wide range of standard X-ray inspection systems to cater for hundreds of different products in the food, pharmaceutical and cosmetics industries.

Richard Parmee is founder and CEO of X-ray inspection technology specialist Sapphire Inspection Systems. As well as designing bespoke solutions, Richard and his team provide a wide range of standard X-ray inspection systems to cater for hundreds of different products in the food, pharmaceutical and cosmetics industries.