ROEQ, a leader in mobile robotic equipment, has entered into a new partnership with OMRON, providing top modules and cart systems for the company’s autonomous mobile robot, the LD-250, doubling the AMR’s payload capacity to 500kg (1,102lbs).

Vissenbjerg, Denmark, September 28th, 2022: Businesses deploying the OMRON LD-250 autonomous mobile robot (AMR) now have a powerful new option to dramatically increase payload without having to invest in a larger, more expensive AMR solution. The ROEQ solution with the new TMC500 top module and Cart500 developed for the OMRON LD-250, not only doubles the AMR payload, it also provides a standardized, safe, and flexible solution for internal logistics tasks.

“This exciting new relationship with ROEQ gives our customers access to fast and cost-effective options for their toughest mobile automation initiatives,” says Kyle Hable, Group Product Manager, OMRON Robotics and Safety Technologies, INC. “OMRON customers around the world depend on our mobile robots for their flexibility, reliable performance, and best-in-class fleet management. ROEQ’s global presence is a perfect match to aid customers with successful autonomous intralogistics solutions.”

Michael Ejstrup Hansen, Managing Director at ROEQ, emphasizes how the new product and OMRON partnership is part of a ROEQ strategy to expand its mobile robotic equipment (MRE) solutions to more AMR brands:

“As a leading quality global brand of AMRs, OMRON is a natural partner for us,” he says. “We developed the cart solution for the LD-250 due to its flexible use and the clear benefits that it adds in both automotive manufacturing, digital and semiconductor industries, food and consumables, warehouse and logistics, and medical verticals.”

Released in 2019, the LD-250 is a fast-growing solution within its performance class. OMRON is one of the AMR pioneers, having sold its first mobile robot fleet in 2013, a fleet still in operation today.

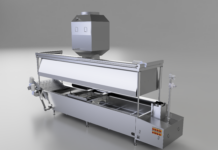

The ROEQ TMC500 solution consists of a top module and the ROEQ Cart500. The solution is versatile, with free-space pick up and mounting holes on the Cart500 for attaching crates and shelves on top of the cart. The robot can dock to the cart from both ends – for greater logistics efficiency – and has easy access to the emergency stop button for cargo up to 120 cm (47.2”). The ROEQ solution comes with software for easy and consistent setup of the system, enabling a seamless integration between the ROEQ TMC500 and the OMRON LD-250. The software includes ROEQ Assist and ROEQ safety zones definitions and the solution works with the OMRON operating panel.

“With this new product offering and partnership, we look forward to providing OMRON customers with a powerful and cost-effective solution,” says Michael E. Hansen, emphasizing how the ROEQ MRE enables compact AMR models to transport heavier load while maintaining maneuverability even in narrow spaces.

The ROEQ TMC500 system for the OMRON LD-250 is expected to be available by the end of 2022.

About Omron Robotics and Safety Technologies, Inc.

Omron Robotics and Safety Technologies was formed in 2019 as a combination of the Omron safety and Omron robotics businesses. As one of the leaders in industrial automation, Omron Robotics and Safety Technologies offers industrial, collaborative, and mobile robots, as well as sensing technology

solutions to help customers achieve the highest levels of efficiency and safety possible. These solutions are all powered by state-of-the-art software and programming platforms that are both highly powerful and easy to use. The goal of this organization is to help build a new manufacturing environment where people and robots work safely and in harmony.

About ROEQ

ROEQ develops off-the-shelf equipment for autonomous mobile robots (AMRs), designed to optimize automated internal logistic workflow e.g. between storage and production. ROEQ was founded in 2017 and is a 100% Danish-owned company with the majority of the robotic components also supplied by Danish companies. Today, ROEQ develops, manufactures, and sells its products in nearly 40 countries through more than 100 distributors.

The ROEQ range of top modules, cart, rack, lifter and roller solutions make it possible for an AMR to safely and reliably transport and transfer loads between workstations with no human involvement. ROEQ equipment is used in the industrial and logistics sector, as well as the healthcare sector.