- Get quick insights from large high-dimensional datasets from our new Event Analytics capabilities.

- Enable everyone in operations to address complex use cases, such as energy management, OEE, and event-based tag reporting with Custom Calculations.

- Get a 360° view of operations and bring shift teams closer to operational data by integrating Shiftconnector® to your contextual data layer.

Houston, Texas, Hasselt, Belgium, and Darmstadt, Germany—28 March 2024—TrendMiner, the advanced industrial analytics platform powered by AI, is marking a significant advancement in event analytics capabilities with the launch of its 2024.R1 release.

Our latest update helps process manufacturers streamline operations by expanding the number of addressable use cases within our user-friendly software environment. It helps users generate quick insights into the relationship between production events and features new ways to extract aggregated information from sensor-generated data. With this update, companies can build an enhanced data layer for extracting ad-hoc insights and develop solutions that provide value throughout the factory, from the control room to the board room. The new 2024.R1 release also adds an enhanced overview of the shop floor by adding Human Intelligence from Eschbach Shiftconnector® as contextual data to available time-series data. This provides users with a 360-degree view and full control over the production process.

“With the 2024.R1 release, we are doubling down on our commitment to providing our users with the most intuitive and powerful analytics tool on the market. The integration with Eschbach Shiftconnector®, which has already proven to be successful at Bayer, brings a new layer of insights to our analytics and empowers users to seamlessly incorporate shift information into their analysis. Combined with the addition of event analytics, TrendMiner is enhancing both the precision and relevance of the insights being generated.”

–Rob Azevedo, Head of Product Marketing, Strategic Alliances

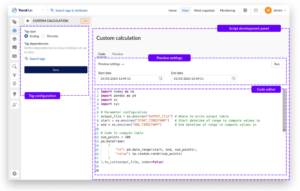

Custom Calculations

As companies grow in analytics maturity, they also can address more advanced use cases. These include energy management, Overall Equipment Efficiency (OEE), shift-based reporting, and non-linear soft sensors. For quick insights on these areas of operational performance, TrendMiner now features Custom Calculations. Users can generate time-series tags in a high-code interface for more complex formulas. They can be used just like any other tag in TrendMiner: For graphical visualization, searching, monitoring, or creating a dashboard.

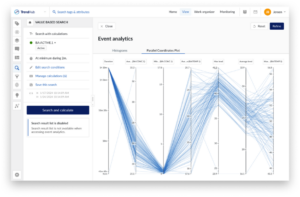

Better Visualization of Process Events

With the growing success of advanced industrial analytics, companies are gathering more data to get deeper insights in operations. TrendMiner’s new Event Analytics module helps users get an overview of large, high-dimensional datasets. It provides operational experts with new ways to calculate, visualize, and refine their data through histograms and parallel coordinates. These highlight distributions and correlations of the data that make root-cause analysis simpler, provide more possibilities for monitoring process conditions, or offering a chance to simply explore the data.

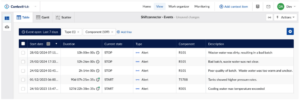

Seamless Integration with Eschbach Shiftconnector®

Our new integration with Eschbach Shiftconnector® provides operational experts with an enhanced view of the situation on the shop floor with information typically siloed in shift logs for analyzing operational performance. This new connection links the shift information and Human Intelligence from the Shiftconnector® platform as contextual events to the time-series data in TrendMiner’s Enhanced Data Layer. Operational experts can investigate incoming Shiftconnector® data in more depth and dimension by providing access to the equipment data.

Further Information

For details about all the new capabilities and improvements in the TrendMiner 2024.R1 release, visit www.trendminer.com. Users of the TrendMiner software will get more information via other communication channels. Learn more about this release in our upcoming webinar at 4 p.m. CET (10 a.m. EDT) Wednesday, April 3, 2024. Register here.

About TrendMiner

TrendMiner, delivers advanced industrial analytics software to optimize process performance in chemical, petrochemical, oil & gas, pharmaceutical, food & beverage, metals & mining, water & wastewater, and other process manufacturing industries. TrendMiner unlocks the full potential of IIoT (Industrial Internet of Things) data infrastructure, regardless of vendor, and taps into the available human intelligence for making data-driven decisions. The solution includes standard integrations with a wide range of data sources, such as OSIsoft PI, Yokogawa Exaquantum, AspenTech IP.21, Honeywell PHD, GE Proficy Historian, Wonderware InSQL, Cumulocity, Aveva Data Hub, AWS S3, AWS IoT SiteWise, Amazon Timestream, Microsoft Azure Data Lake, Azure Data Explorer, Microsoft Fabric, and SAP’s S/4 HANA, and DMC.

TrendMiner empowers everyone in manufacturing operations across multiple locations with powerful yet intuitive capabilities to iteratively generate and validate real-time context-aware time-series insights individually and as a team. Search, diagnostic, and predictive capabilities help speed up root cause analysis, define optimal processes, and configure early warnings to monitor production 24/7. TrendMiner helps operators make data-driven decisions to improve production quality, meet business objectives, and increase profitability.