When a food manufacturer came to FlexXray with concerns about a missing piece of Intralox, FlexXray ended up finding more than either of them expected.

When a client who provides sausage patties to many of the largest fast-food chains in the nation reached out to FlexXray, they already knew that they had a problem. What they didn’t know is how significant the problem was — and what kind of catastrophe they were about to avoid.

FlexXray, the Arlington, Texas-based company that provides X-ray inspection for food companies, has been serving some of the largest manufacturers in the industry since 2001.

With equipment that can detect particles of various foreign materials and find contaminants at 0.8 mm or smaller in diameter, the company can step in when manufacturers realize that they have a problem. FlexXray uses its custom X-ray technology to help identify the location of the contaminant and then determine the necessary steps to prevent the contaminated product from reaching the consumer.

In this case, the sausage manufacturer realized that it was missing part of an Intralox conveyor belt, but wasn’t sure where it was located. The manufacturer contacted FlexXray to determine what steps they could take to save as much product as possible while locating and eliminating the plastic contaminant.

“It would be virtually impossible to find the missing piece in-house without a complete visual inspection,” says Kye Luker, Vice President of Operations, Foreign Material Inspection at FlexXray. “The bags of sausage were already in boxes and it just wasn’t possible to find it that way.”

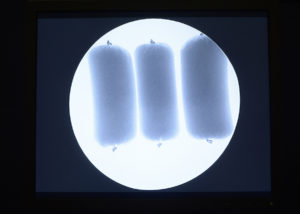

Instead, the food manufacturer identified all of the sausage that had been processed since the last inspection and sent six loads of bracketed product to FlexXray for inspection. By removing all the bags from the boxes and placing them in a single layer on an X-ray machine, FlexXray was able to inspect all of the bags, both by machine and by visual inspection.

Instead, the food manufacturer identified all of the sausage that had been processed since the last inspection and sent six loads of bracketed product to FlexXray for inspection. By removing all the bags from the boxes and placing them in a single layer on an X-ray machine, FlexXray was able to inspect all of the bags, both by machine and by visual inspection.

More Than They Bargained For

Luker says they immediately had good news for the customer: the missing part of the conveyor belt was in the packaging and not in the patties themselves. However, FlexXray had other news for the client as well.

“We found a whole bunch of other things in addition to what they were looking for,” Luker says. “Since this manufacturer is a supplier for fast food companies, it would have led to a lot of consumer complaints and all kinds of problems both for our customer and for the fast food restaurant.”

Among the other contaminants found in the sausage were additional pieces of metal and bone fragments. FlexXray was able to locate the contaminants, remove them from the product for customer reporting, and dispose of the contaminated product before it could be distributed to fast-food customers.

Safety Through Prevention

FlexXray’s findings kept their client from facing consumer complaints, a recall, potential lawsuits and possibly even loss of their business.

Because FlexXray was able to locate specific materials, the food manufacturer was able to determine that the bone fragments had come from internal suppliers. The manufacturer then had to begin investigating which products came from each supplier to see where the contaminated product originated.

Because FlexXray was able to locate specific materials, the food manufacturer was able to determine that the bone fragments had come from internal suppliers. The manufacturer then had to begin investigating which products came from each supplier to see where the contaminated product originated.

With the discovery of metal fragments, the food manufacturer began an investigation to determine if the metal had come from the meat or ingredient suppliers, or if the contamination occurred in their own manufacturing process.

“They found out that they were the source of their metal contamination, so then they had to look at how much product they had that might be contaminated,” Luker says.

“We ended up inspecting dozens of truckloads to make sure there were no more contamination issues and then ensured that [the manufacturer] wasn’t going to have any more problems with it.”

Working from its 60,000-square-foot facility, FlexXray was able to complete the inspection quickly, thanks to its large labor force and number of machines FlexXray could devote to the inspection. With 12 machines, and the ability to turn a truckload in as little as four hours, FlexXray was able to inspect over 26 truckloads in less than two weeks — preventing the customer from missing any distribution deadlines.

“The problem was resolved, and all the contaminated product was eliminated,” Luker says. “The fast food restaurant was protected, and the customer was able to fulfill all their orders with a product that they knew was safe.”

Chris Keith is the VP of Sales, Marketing and Customer Service at FlexXray®. Based in Arlington, Texas, FlexXray is the nation’s leading foreign material X-ray inspection company, serving a majority of the largest food companies in North America.

Email: [email protected] | www.FlexXray.com