Uzwil (Switzerland), May 11, 2020 – In just six weeks, Bühler transformed its physical interpack program into a fully digital experience. It has certainly been a very steep learning curve for the company, but one that will give Bühler’s partners and customers access to new services for operational efficiency and capacity improvement, new product proposals to delight consumers, and inspiration to ensure the long-term sustainability of our global food supply. All of this from the safety and convenience of their own homes and offices. The publicly accessible Bühler Virtual World, with its content-rich program, will open its digital doors from May 12-15 at: virtualworld.buhlergroup.com.

The Virtual World addresses three key questions Bühler has asked itself for 2020:

How does Bühler increase its contribution to the business resilience of its industry in the next 24 months?

“In today’s world, we see it as our responsibility to ensure the continuity of food supply chains, but also to keep business afloat by enabling close collaboration among industry partners and with our customers,” says Germar Wacker, CEO of Bühler Consumer Foods. With digital capabilities underpinning a service portfolio increasing yield and capacity, ensuring consistent product quality and reducing unplanned downtime, waste, and energy consumption Bühler can contribute to support its customers to deliver the strong demand they experience today while securing their operational results. Bühler’s digital platforms myBühler and Bühler Insights will support business resilience by enriching the physical world with the capability of digital solutions.

How can Bühler support its industry to bounce back strongly once the new normal is established?

Relevant differentiation is the key to unlock consumer demand and is transforming the food industry at an extraordinary rate. Natural, clean label, on-the-go, regional origin, increasing varieties, bite size, healthy, organic, and local are all trends of importance. Bühler food technologists will present a variety of products that address these trends, from savory wafer products, low fat products, filled wafer pillows, eatable coffee cups, vegan chocolates, to plant-based chicken pieces, to mention but a few. “A combination of flexible assets, higher operational efficiency and differentiated offerings will support our industry to return successfully to the new normal”, says Wacker.

How can we build a sustainable food industry to nourish and delight 10 billion people in 2050 within the planetary boundaries?

Everyone including Bühler must embed sustainability in all their decisions. Economy, nature, and society must be considered equally. “We are convinced that our sustainability goals will produce good business models, and we will make this case at the Bühler Virtual World,” says Stefan Scheiber, Bühler Group CEO. Bühler focuses all research and development spendings on its targets of reducing waste, energy, and water consumption in its customers’ value chains by 50%.

New solutions such as the modular moulding line ChocoX deliver the flexibility needed for high innovation rates with the efficiency of a mass production line. The new SWAKT-Eco wafer oven reduces energy consumption by 30%. Bühler’s service portfolio for chocolate mass has increased Overall Equipment Effectiveness (OEE) by up to 30% in some cases. The company’s SnackFix and ChoCoat solutions reduce changeover times to only minutes. Bühler’s cross-value-chain capabilities in plant protein processing provide nutritious options to meat with a CO2 footprint that is less than half of chicken or 15 times less than beef.

Additionally, Bühler estimates that Virtual World saves around 10,600 tons of greenhouse gas emissions compared to the physical event, equivalent to the compensation output of 175,000 trees. Bühler will create a sustainable food industry.

The highlights of the Bühler Virtual World

As a solution provider, Bühler has grouped the innovations of its Virtual World into four key topics:

• How to capitalize on market trends with high flexibility, fast changeovers, and integrated solutions.

• How to reach the highest efficiency with best Overall Equipment Effectiveness (OEE).

• How to manufacture products reliably with documented food safety.

• How to improve sustainability with reduced consumption of energy, water, and waste.

ChocoX: Highly flexible, modular solution for moulding

Following a “plug-and-produce” concept, the new moulding line, ChocoX (pronounced “Choco Cross”) marks a breakthrough in the industry with its consistently modular approach. ChocoX can be installed on site within a week, reducing implementation time by 80%. ChocoX slashes the time for a line expansion by half, compared to previous solutions. Its modular structure allows for great flexibility. Modules can be changed or cleaned in as little as 30 minutes and rearranging the process chain only takes between 30 to 120 minutes. Bühler will communicate more on ChocoX during this week.

Customer services at the click of a button

The myBühler portal offers customers 24/7 access to all the information relevant to their technologies and equipment. myBühler streamlines the purchasing process with pricing and material information and online ordering. Customers operating former Haas solutions will soon be able to connect to myBühler as well. It is far more than a standard customer portal. It is the starting point and the one-stop-shop for all digital solutions, including product information, eMaintenance, e-Training, and eService such as Bühler’s Remote Guidance. Smart glasses enable Bühler’s specialists to instruct professionals at customer sites remotely. And Bühler guarantees first-level-support within two hours.

Saving energy, water, and waste

Bühler is presenting a wide range of innovative product formulations, from chocolate mass to enrobed baked products, from moulded products to wafers and biscuits. All of them will be displayed with experts explaining their sustainability and production benefits. Bühler’s aim is to reduce energy use, water consumption, and waste in customers’ value chains by 50% by 2025. “We are convinced that our sustainability goals will produce good business models, and we will make this case at the Bühler Virtual World,” says Scheiber.

Among the sustainable solutions that will be presented during the virtual fair is the Franz Haas MTA. It can produce eatable and biodegradable packaging made from wafers and helps lower the use of single-use plastic. An estimated 20 billion disposable coffee cups are used and thrown out every single year. And, the SWAKT-Eco wafer-baking oven reduces emissions by 90%. It also uses 30% less energy. These are just a few of the innovations to be unveiled.

Food safe designs incorporate new concepts and latest technology such as laser cleaning for SWAKT-Eco or the new batch roaster Solano that combines three process steps in one solution: pasteurizing, roasting, and drying. Bühler guarantees a bacterial reduction of at least 99.999% with the Solano.

Heralding a new era with the Bühler Virtual World

Equally innovative as the new solutions and services is the way Bühler will showcase them and communicate with its customers and partners during the Bühler Virtual World. This virtual trade fair combines a live event program, a virtual solution space, and video conferencing features. “Today, with greater urgency than ever, the world is relying on food industries to run like clockwork,” says Scheiber. “It has to ensure solid production chains and reliable output. The industry also needs to adapt and learn how to innovate together as partners, even when it is physically impossible.” Bühler developed the Virtual World to deal with these challenges in a collaborative manner and bring important industry stakeholders together. “We want to show our customers that they can rely on us even in times of crisis, be it for new product developments, for servicing their solutions, or when digitalizing their plants for the new normal we are now learning to live in,” says Scheiber.

Customers and visitors can look forward to exploring the virtual booth. They are free to attend the livestream program featuring keynotes on digitalization and sustainability and delve deep into service solutions and special application areas that will be presented by expert food technologists.

For trade media: Virtual booth tour today and press conference on Thursday

Today at 4:30 p.m. CET, Bühler will give journalists an exclusive booth tour before Stefan Scheiber and Germar Wacker will officially open the Virtual World on May 12 at 9 a.m. CET. Journalists are free to watch Tuesday’s and Wednesday’s full program here (no registration needed). All contents can be accessed following the event.

Thursday, May 14 at 4 p.m. CET, Bühler and Premier Tech will present the next steps of their strategic partnership in a virtual press conference. Please register for it here: https://www.buhlergroup.com/

Please access Bühler Virtual World here.

You can view the Bühler Virtual World live program here.

Image to download: Stefan Scheiber, CEO Bühler Group

Image to download: Germar Wacker, CEO Consumer Foods, presenting at Bühler Virtual World

Image to download: Germar Wacker, CEO Consumer Foods

Image to download: Ian Roberts, CTO Bühler Group, presenting at Bühler Virtual World.

Image to download: Ian Roberts, CTO Bühler Group

Image to download: Key visual of the Bühler Virtual World

Image to download: Booth detail of Bühler Virtual World

Image to download: The center of the virtual booth

Image to download: ChocoX is Bühler’s new moulding line with a “plug-and-produce” concept. ChocoX can be installed on site within a week, reducing implementation time by 80%.

Image to download: The Franz Haas MTA can produce eatable and biodegradable packaging made from wafers.

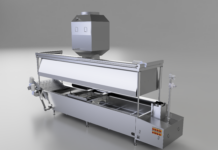

Image to download: The SWAKT-Eco wafer-baking oven reduces emissions by 90% and uses 30% less energy.

Image to download: Bühler’s new batch roaster Solano combines three process steps in one solution: pasteurizing, roasting, and drying. Bühler guarantees a bacterial reduction of at least 99.999% with the Solano.

Image to download: SnackFix is one of Bühler’s solutions that reduce changeover times to only minutes.

Image to download: myBühler is the one-stop-shop for all digital solutions, including product information, eMaintenance, e-Training, and eService.

Image to download: Bühler’s Remote Guidance solutions also include smart glasses that enable Bühler’s specialists to instruct professionals at customer sites remotely. Bühler guarantees first-level-support within two hours.

Media contact:

Burkhard Böndel, Head of Corporate Communications,

Bühler AG, 9240 Uzwil, Switzerland

Phone: +41 71 955 33 99

Mobile: +41 79 515 91 57

E-mail: burkhard.boendel@buhlergroup.

Dalen Jacomino Panto, Media Relations Manager

Bühler AG, 9240 Uzwil, Switzerland

Phone: +41 71 955 37 57

Mobile: +41 79 900 53 88

E-Mail: dalen.jacomino_panto@

Markus Reber, Media Relations Manager,

Bühler AG, 9240 Uzwil, Switzerland

Phone: +41 71 955 12 44

Mobile: +41 79 864 29 41

E-mail: [email protected]

Trade media contact:

Tracey Ibbotson, PR Executive,

Bühler UK Limited, London, England

Phone: +44 (0) 1992 537 421

E-mail: tracey.ibbotson@buhlergroup.

# # #

About Bühler

Billions of people come into contact with Bühler technologies as they cover their basic needs for food and mobility every day. Two billion people each day enjoy foods produced on Bühler equipment; and one billion people travel in vehicles manufactured using parts produced with Bühler machinery. Countless people wear eyeglasses, use smart phones, and read newspapers and magazines – all of which depend on Bühler process technologies and solutions. Having this global relevance, Bühler is in a unique position to turn today’s global challenges into sustainable business. Bühler contributes to safely feeding the world and is doing its part to protect the climate, producing machinery that makes cars, buildings, and machinery more energy efficient. Its aim is to reduce energy, waste, and water in its customers’ value chains by 50% by 2025. Bühler’s purpose is creating “innovations for a better world.”

Bühler invests up to 5% of turnover into research and development. In 2019, some 12,800 employees generated a turnover of CHF 3.3 billion. As a Swiss family-owned company, Bühler is active in 140 countries around the world and operates a global network of 98 service stations, 32 manufacturing sites, and 25 application centers. In 2020, Bühler celebrates its 160th anniversary.