Process manufacturers are optimistic about the future, but see challenges related to changing regulatory conditions (especially trade), increasing pressure for traceability, and the talent shortage, according to Sage’s 2019 manufacturing report, “Riding the wave of uncertainty: How process manufacturers are planning for a brighter future.” To drive growth in the face of these challenges, companies are turning to technology.

To learn more about the results as they pertain to the food and beverage industry, we spoke with Rob Sinfield, the Vice President of Product for Sage Business Cloud X3.

Optimism in the face of uncertainty

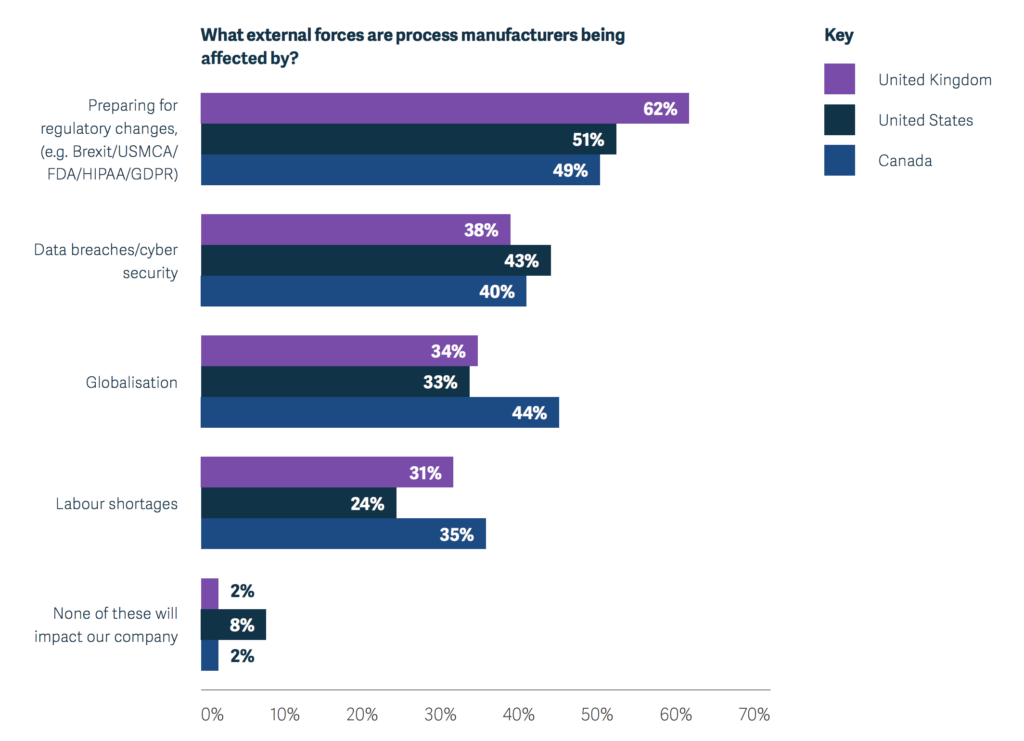

Process manufacturers are currently facing a good deal of economic and political uncertainty, the report revealed. Specifically, manufacturers cited preparing for regulatory changes, especially trade, as the top external force affecting the industry.

Despite this uncertainty, manufacturers are feeling good about the future. “Probably the most surprising thing that came out of the report was the fact that food and beverage manufacturers are so positive,” Sinfield said. “A lot of people assume that manufacturing is very down, it’s very depressed….It was really interesting to see positivity with 80% of the respondents. I think it was 80% of them saying, ‘Hey, we’re positive, we’re really excited about where things are going, and we’re really looking forward to moving forward.’”

Opportunities and challenges in locally produced, traceable products

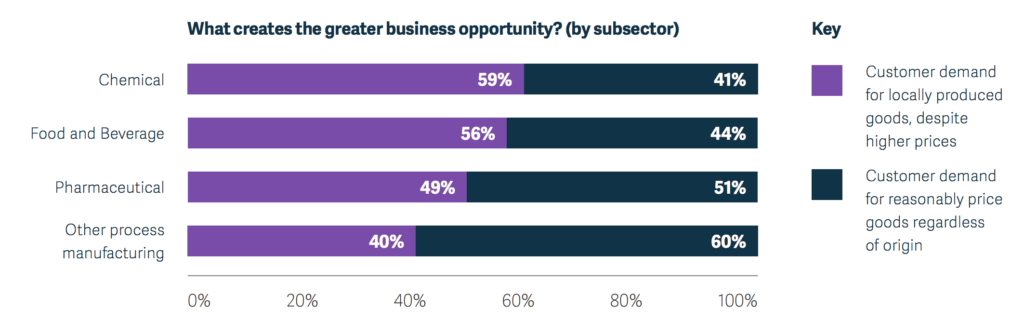

One of the reasons for positivity is that manufacturers see new opportunities, for example, to satisfy the growing demand for locally produced goods, for which consumers are willing to pay premium prices. In the food and beverage sector, 56% of respondents thought there was more business opportunity in locally produced goods, despite their higher prices, compared to 44% who see more opportunity in reasonably priced goods regardless of origin.

To capitalize on these opportunities, many manufacturers are nearshoring their operations as much as possible. Sometimes this involves creative solutions, like acquiring operations in distributed areas. Sinfield gives an example of a UK produce company that has been increasing their ability to satisfy the demand for local by bringing more local producers under their corporate umbrella.

Controlling the supply chain also helps manufacturers achieve traceability, which is quickly becoming table stakes for the food industry.

“There’s more and more pressure on this idea of traceability and provenance,” Sinfield said. “Where does the food that I’m selling come from? Where are the raw materials sourced? How are they produced? Can I track information about pesticide levels? Etc., etc.”

Being able to answer these questions is particularly important, Sinfield said, for new companies entering the market and for companies looking to succeed in international markets, especially in Asia. “Asia went through a period where there were [several] food scares. If you’re going to launch a new product into the Asian markets, they expect you to be able to provide provenance. You must be able to show that if you’re a new entrant. But, equally, if you’re a new entrant and you can show [provenance], people will spend more. They will pay a premium for that knowledge, that traceability, and that additional comfort they get.”

Of course, for food and beverage companies, supply chain traceability isn’t just about new opportunities — a lack of traceability can lead to serious problems, up to and including costs to human life.

When it comes to risks, however, Sinfield is concerned that manufacturers may have their priorities out of order. Food and beverage respondents cited loss of brand value as the biggest risk of not having transparency. Litigation was second, while cost to human life was third, just barely ahead of not meeting regulations.

“For me…as a consumer, as somebody who has children, that’s incredibly worrying,” Sinfield said. “I think this is where the outcomes were a bit skewed…[with companies] strangely enough putting the cost of human life lower than…loss of brand value. That [raised] some interesting questions, and I’d love to talk to some of these industry leaders to see what they say about this.” (So would we. If you’re a food processor or manufacturer who would like to discuss these results, get in touch at [email protected].)

Finding solutions in technology

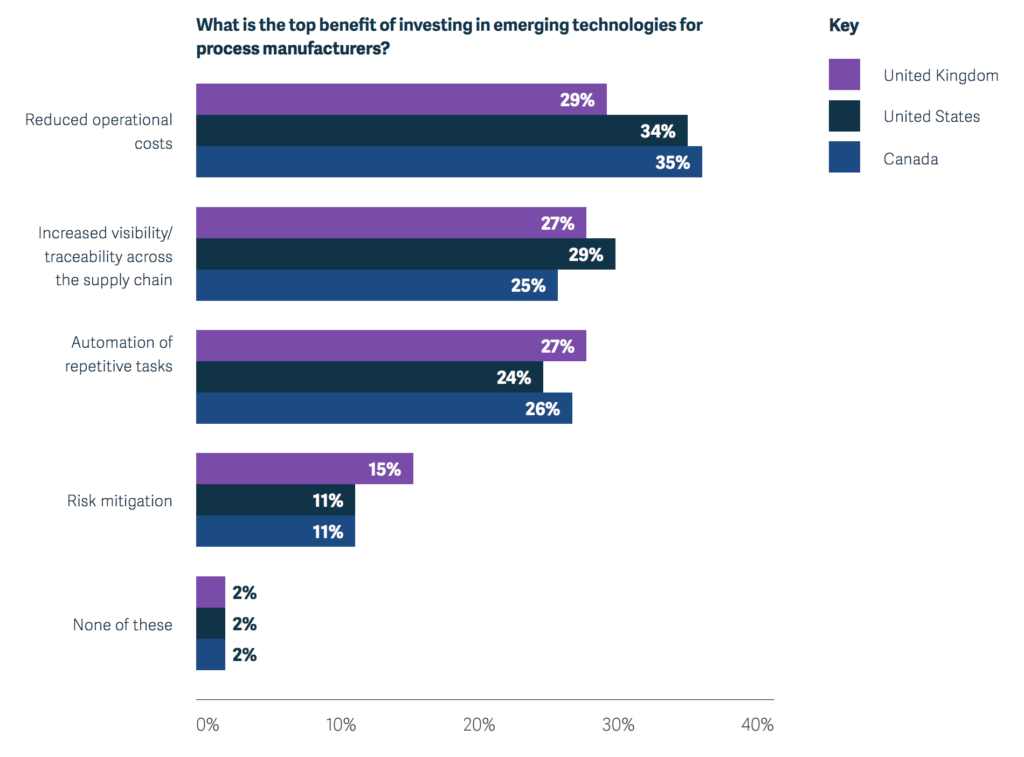

The good news is that solving the traceability problem will mitigate all of the risks at once. Increased visibility across the supply chain is the second most important benefit of investing in emerging technologies, second only to reduced operational costs.

“A lot of these companies right now are actively asking us for things like blockchain technology so that they can prove provenance,” Sinfield said. “[Blockchain] is being used more and more in the food and beverage space to create irrefutable evidence of where a product has come from, where it’s gone, and how it was sourced.”

The ongoing talent crunch

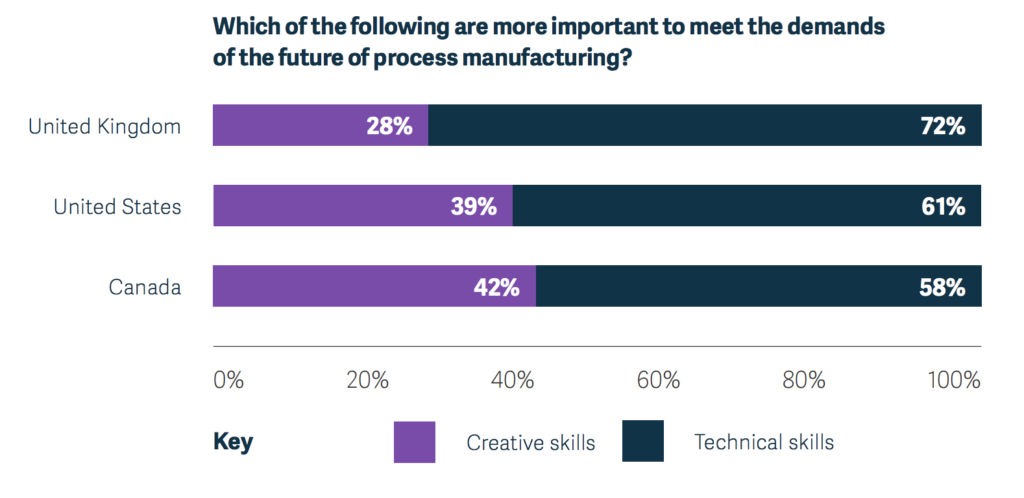

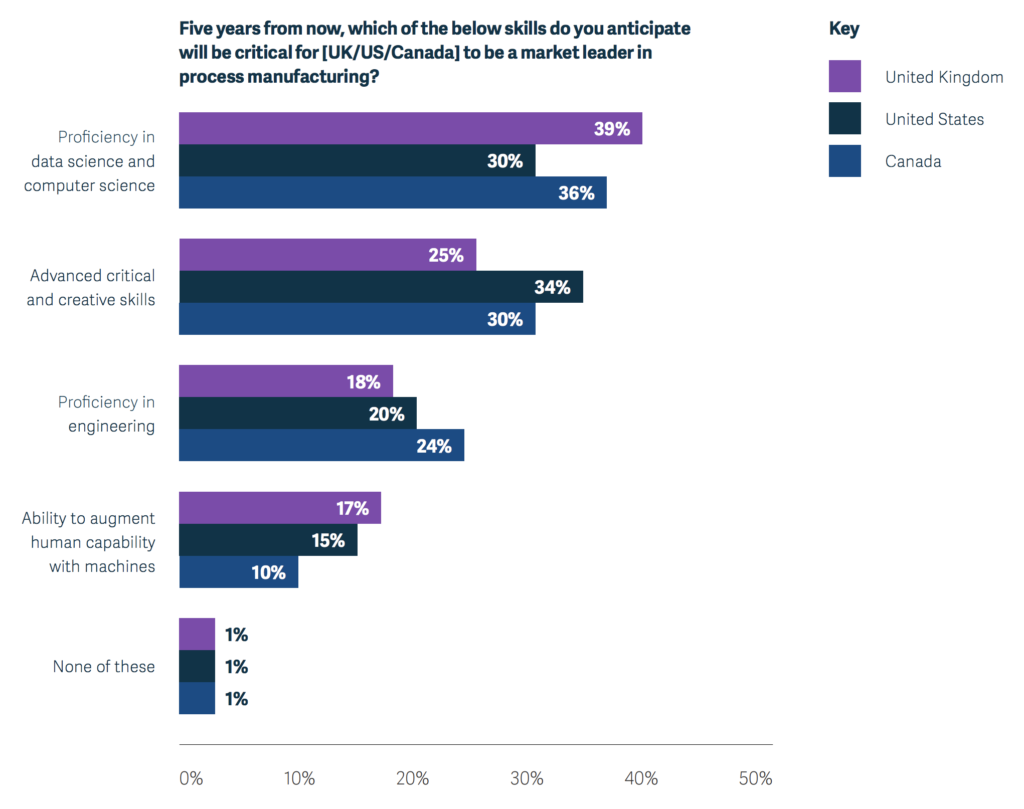

Along with improving traceability, solving the ongoing talent shortage continues to be a main priority of food and beverage manufacturers. One particularly interesting finding from the survey is that the types of skills employers are looking for seem to be shifting from creative skills back to technical skills.

“The majority of the focus is now on recruiting technical skills,” Sinfield said. “I think we’ve put so much emphasis on creative skills and bringing in people who can think in different ways and bring creative capabilities that we’ve almost lost a little bit of the technical know-how that these food and beverage manufacturers need.”

One of the reasons that food and beverage has been having trouble finding talent is that manufacturing isn’t perceived as a very exciting industry. But, manufacturing today is much different from what it was in the past.

Sinfield gives the example of a recent food expo where he got the opportunity to try food made using additive manufacturing, aka 3D printing, technology. “The skills for [3D printing food are] significantly different from, say, the skills of somebody who would be pulling together recipes. [There are] technical engineers who write the code to program the 3D printer….The skill sets are changing because of the way the manufacturing process is changing.”

In future, these technical skills will become even more crucial. Overall, proficiency in data science and computer science is predicted to be the number one skill set that will be critical for companies looking to be market leaders in the next five years.

“If you look at something like proficiency in data science and computer science, in the food and beverage industry five years ago, that wouldn’t have ranked anywhere near the top,” Sinfield said. “In the United States, it’s the second-highest sought after skill….There’s definitely a switch from it being focused on somebody who can operate a machine or has basic technical engineering skills to someone who is more of a data scientist, [who] understands data, is aware of how it works, etc.”

Trade, traceability, talent, technology — these four Ts summarize well what’s top-of-mind for processors and manufacturers today. For more insights into these issues and the ways the food and beverage industry is tackling them, check out the full report from Sage.

![[Case Study] Are There Gaps in Your Trading Partner Communications When Just Using Your ERP? Learn How to Improve It.](https://foodindustryexecutive.com/wp-content/uploads/2024/12/241201-Food-Ind-Exec-Featured-Image-Placement-2-218x150.jpg)