94% of global manufacturing companies said that Industry 4.0 technologies keep operations running during COVID-19, according to the results of McKinsey & Company’s latest Industry 4.0 survey. More than half (56%) said digital technologies were “critical to their crisis responses.”

For the past four years, McKinsey has been surveying leaders at manufacturing companies worldwide about their Industry 4.0 technology adoption. These companies represent a wide range of industries, including consumer products. Their latest survey, which was conducted 6 months into the COVID-19 pandemic, found that companies fell into three groups in terms of the relationship between their Industry 4.0 adoption and their response to the crisis: win, reality check, or wake-up call.

The winners

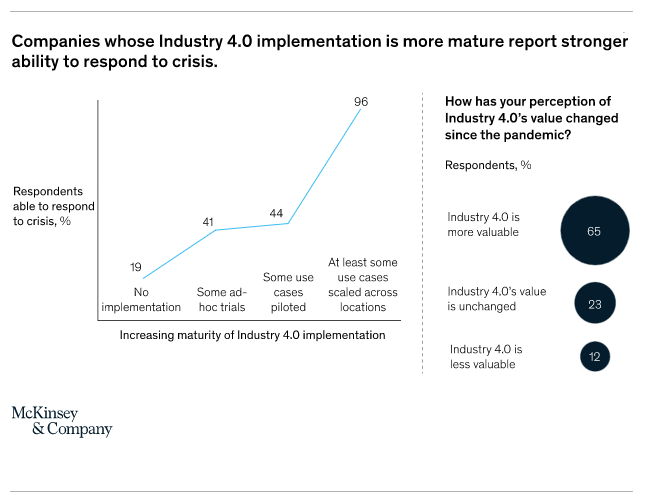

The companies who adopted Industry 4.0 early and had achieved higher levels of implementation when the pandemic hit were more successful in responding to the crisis. Almost all (96%) of companies that had at least some Industry 4.0 technology use cases scaled across locations said they were able to respond to the crisis, compared to only 19% with no implementation. Nearly two-thirds (65%) of respondents said that the pandemic has caused them to perceive Industry 4.0 as more valuable than they did before.

Source: McKinsey & Company

The reality checkers

Many companies realized that they weren’t as far along in their Industry 4.0 implementation as they had reported previously. The number of companies reporting that they had successfully scaled some use cases was down 40%, to pre-2017 levels.

McKinsey suggests two reasons for this change in perception:

- The definition of success has changed. “Industry 4.0 technologies are no longer being measured for their ability to add value during business as usual; instead, they are also expected to prove valuable during trying times such as the COVID-19 crisis,” McKinsey writes.

- Companies may have discovered that they “have further to go than they thought before their implementations are truly fully scaled.” In particular, McKinsey notes that companies may have prioritized speed at the expense of addressing limitations in their underlying technology infrastructure.

The wake-up callers

Companies that had not implemented Industry 4.0 before the pandemic found themselves in a tough situation, which was exacerbated by the crisis. Many of these companies reported halting their Industry 4.0 implementations due to factors including travel restrictions, cash constraints, and team-capacity constraints.

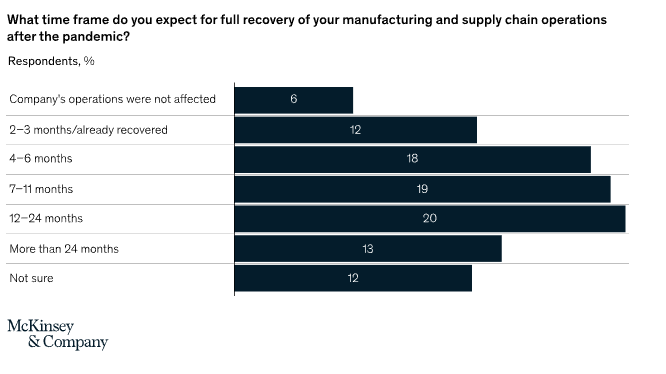

In addition to the Industry 4.0 implementation questions, the survey also asked how long respondents think it will take for their manufacturing and supply chain operations to fully recover. Most people’s predictions fell between 4 and 24 months.

Source: McKinsey & Company

Visit the McKinsey website for more information about Industry 4.0 implementation in manufacturing.