Readco CP Defines Lot by Volume, Weight, Time, and More

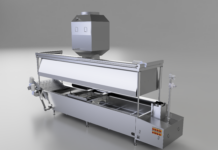

York, PA: Continuous Processors from process equipment manufacturer Readco Kurimoto, LLC, York, Pa. (www.readco.com), enable food, nutrition, chemical, pharmaceutical and other manufacturers to track and trace lots in a continuous processing environment. Devised to support compliance with the FDA Food Safety Modernization Act (FSMA), the Continuous Processors can establish a positive cutoff for lot traceability from nearly any desired point based on volume, weight, time, shift, raw material lot, or other criteria. The lot tracking criteria is pre-programmed using the company’s optional process control system and applied automatically in non-stop operation, 24/7. For reporting, quality control, or in the event of a recall, the system may be instantly accessed remotely or on-site and a particular production lot quickly identified.

Ideal for tracking and tracing cheeses, doughs, candies, vitamins, herbicides, plastic resins, and other products that require or benefit from lot and material traceability, the Continuous Processors eliminate the multiple steps in batch processing that invite contamination and increase risk of a recall. The Readco Continuous Processors, by contrast, mix, blend, react, compound, crystallize, encapsulate, and/or perform other processes with multiple liquid, dry and viscous materials in a single step. The result at discharge meets customer specifications for moisture, texture, color, uniformity, and other properties as targeted.

Custom-engineered for each product and process, the continuous lot traceability systems may be tested at the company’s on-site test laboratory using customer materials and formulations on full-size equipment. Performance is verified in advance with results guaranteed.