Late last year, cultivated meat company Future Meats announced that it could produce chicken breasts for $7.70 a pound, down from $18 a pound just six months prior. In doing so, the company says it became the first to “break the commercial viability cost barrier.”

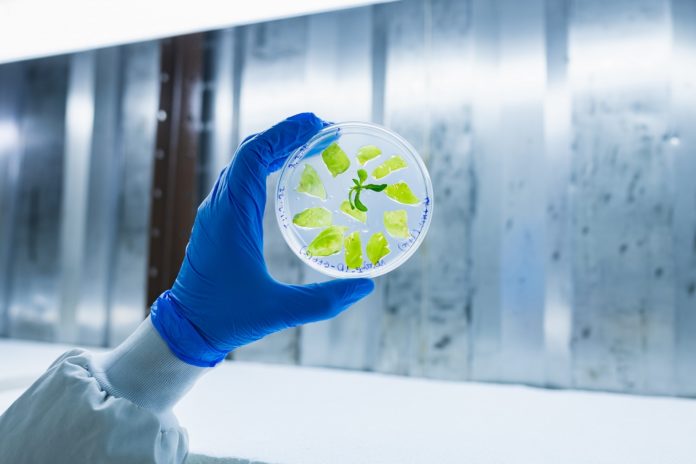

That cost barrier. along with scalability, are the biggest obstacles cultivated meat companies have to overcome. But hope may be on the horizon. Last week, food tech start-up BioBetter announced that it is using tobacco plants to create the growth factors needed for the cellular development of cultivated meat.

The company notes that growth factors are currently collected from livestock, which limits the available quantity, or through fermentation of yeast or bacteria, which requires expensive facilities. Making growth factors easier and less expensive to harvest could significantly bring down the cost of cultivated meat. “The Good Food Institutes determined that approximately a 100-fold reduction in insulin and transferrin costs is required to make cultivated meat economically viable,” BioBettter co-founder Dana Yarden said in a press release. “It is estimated that growth factors and cell-culture media can constitute 55 to 95% of the marginal cost in manufacturing cell-based foods.”

BioBetter says is has burned tobacco plants into bioreactors for expression and large-scale production of the proteins. It notes that tobacco plants “can achieve up to four growth cycles annually and be harvested all year. This translates to more voluminous outputs per square meter of growing space.”

![[Case Study] Are There Gaps in Your Trading Partner Communications When Just Using Your ERP? Learn How to Improve It.](https://foodindustryexecutive.com/wp-content/uploads/2024/12/241201-Food-Ind-Exec-Featured-Image-Placement-2-218x150.jpg)