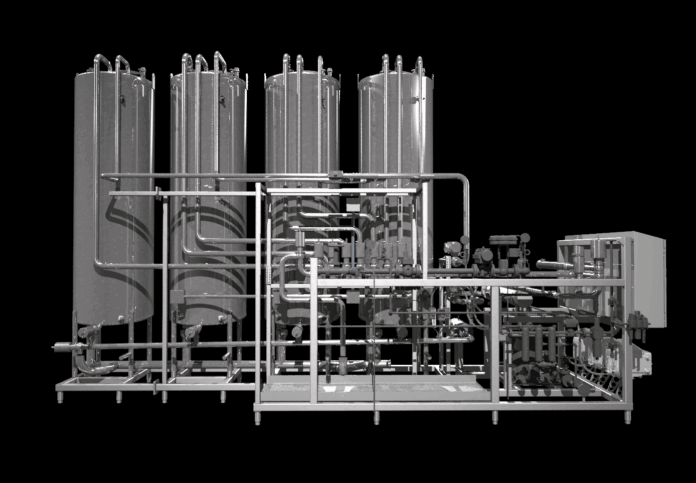

Digitally controlled sanitary equipment cleaning solution reduces resource use, cuts downtime

STRATFORD, Wis. (Sept. 29, 2025) — A&B Process Systems, a JBT Marel brand and industry leader in the design, automation and installation of stainless steel process systems, today unveils the next evolution in clean-in-place (CIP) technology: The CIPure™ Cleaning System. This modular, digitally controlled solution maximizes capacity, minimizes downtime, and greatly improves sustainable operations for food, dairy, beverage and pharmaceutical manufacturers.

CIP systems are essential for food safety by cleaning product contact surfaces to prevent contamination from harmful bacteria and microorganisms. CIPure’s tailored design and advanced monitoring technology was designed to help companies be intentional in their approach to cleaning and potentially add decades of life to their equipment.

“A poorly designed cleaning system results in longer cleaning times, excessive water and chemical use, and increased production downtime,” said Dan Wolff, Manager of Sales Engineering. “Unfortunately, many manufacturers are plagued by ineffective and expensive-to-run equipment. The CIPure Cleaning System was designed to maximize capacity and minimize downtime with state-of-the-art automation and intuitive operability that can be configured to any plant’s specific needs.”

CIPure was created with sustainability top of mind. Built with sustainably sourced materials, CIPure features easy-to-operate, intuitive controls that maximize performance while minimizing water, chemical and steam consumption. Its robust automation is configured to alleviate the operational pains of highly manual CIP systems. It optimizes rinse and wash times, accurately doses and mixes chemicals, and applies an effective recovery process to help reduce environmental impact.

Additional design features include:

- Reducing labor needed. CIPure can be run by as few as one operator for a cleaning cycle who is alerted to any issues identified by the CIPure system.

- Consolidating easily reachable access points for ergonomic efficiency, reducing the need for ladders and scissor lifts.

- Offering more precision with continual monitoring to help ensure cleaning performance as well as waste reduction. The system provides reports and efficiency data to make faster and better decisions.

- Preventative maintenance is optimized through a combination of tracking scheduled and routine maintenance, and real-time system monitoring to alert for immediate service needs.

Like other JBT Marel solutions, customer support for CIPure goes well beyond the implementation phase. JBT Marel offers post-installation audits to ensure continued optimal results and provide adjustments to the machine’s automation features for specific companies’ needs.

For more information about A&B Process Systems’ innovative clean-in-place technology, please visit https://www.jbtc.com/foodtech/

# # #

About JBT Marel

JBT Marel (NYSE: JBTM) is a leading global technology solution provider to high-value segments of the food & beverage industry. JBT Marel brings together the complementary strengths of both the JBT and Marel organizations to transform the future of food. We provide unique, holistic solutions by designing, manufacturing, and servicing cutting-edge technology, systems, and software for a broad range of food and beverage end markets. Our aim? To create better outcomes for customers by optimizing food yield and efficiency, improving food safety and quality, and enhancing uptime and proactive maintenance, all while reducing waste and resource use across the global food supply chain. We employ approximately 11,700 people worldwide and operate sales, service, manufacturing, and sourcing operations in more than 30 countries. For more information, please visit https://welcome.