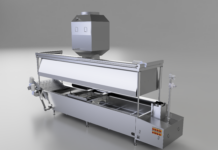

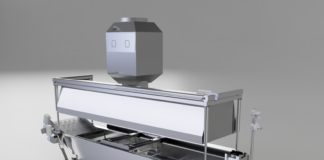

Gericke Option Speeds Integration of High Volume Liquids with Dry Products

Somerset, NJ: Process equipment manufacturer Gericke USA, Somerset, NJ (www.gerickegroup.com), has introduced an optional mixer dispersing system that promotes highly efficient distribution and optimal dispersion of liquids and agglomerated solids into dry particles. Featuring a patented design, the Gericke dispersing system sets rotating blades on the interior of the mixer’s front door that harness the high product pressure at the entry to automatically disperse the ingredients evenly throughout a large area. The Gericke innovation is ideal for cutting blocks of fat, breaking lumps of fibers, deagglomerating egg powder, and for adding high volumes of liquids, among other applications, when a uniform distribution of multiple ingredients and fast batch cycle times of 30 seconds or less are required.

Available on the company’s GMS Multiflux® double shaft mixers and GBM single shaft mixers, the new dispersing system may be easily accessed for cleaning by opening the full-size door, which also invites complete access to the mixing rotors, mixing chamber and the entire interior. The sanitary mixers and dispersing system knives are manufactured from stainless steel and meet FDA and GMP requirements. Product and performance testing using the mixer dispersing system are offered at the company’s test center.

For more information or to schedule a demonstration, contact Gericke USA, Inc., 14 Worlds Fair Dr. Suite C, Somerset, NJ 08873-1364; 855-888-0088; sales.us@